Although I find that claim plausable, to an extent, there is a point that doesn't make sense. I don't have the proper physics background to express my point, so a short history lesson if I may. . .

I am not a machinist, I am a model builder who occasionally works with metal stock. I had used a UniMat (DB-200) for years before desiring to cut threads. A UniMat will cut threads, sort of, but it is done with a follower on a form, not really a satisfactory way to do things for the pitches I wanted. Actually, I had wanted to cut threads for a long time but the attachments for a UniMat were beyond my means, until. . .

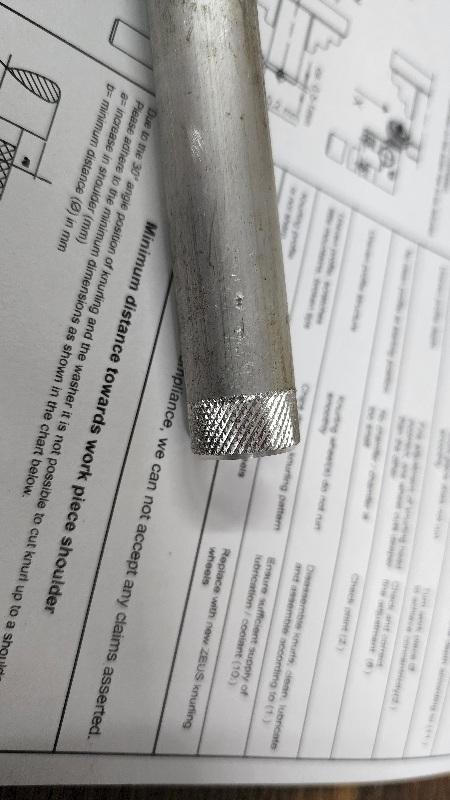

In the early '90s, funds allowing (good job, reasonably secure) I acquired a small (9X19) lathe that could cut threads. At that time I took an interest in knurling. My early attempts at such were to cut a very light 16 TPI (1.5 mm pitch) thread, running first forward(right hand) and then cutting a left hand thread. At that point, I discovered there was no way for the low end machine to cut left hand threads. No way to reverse the lead screw. . . Following the "invention" of a reverse tumbler, I was able to do so but the results were not really satisfactory. In fact, the results were downright disgusting. At that point, I seriously investigated a knurling tool, ending up with a scissors type because of the light size of my machine.

With all that said, the configuration of the displayed tool doesn't fit my sensabilities. To "cut" a knurl would equate to a multipass threading operation operation, requiring a traverse in both right hand and left hand directions. I can see where the knurling "teeth" could cut a multi-pass groove(light thread), in one direction. But to cut in the reverse direction, reversing the leadscrew would be necessary. In essence, making two passes to get the desired form.

The above is not a very clear description of what I see in my mind's eye. For this, I apologize. . . Basically, cutting a knurl doesn't seem possible without that reverse pass. I can see where the tool would cut the desired form, but it would be one sided without that reverse pass. That is why I stand my ground to it being a modification of the pressure type tool, with displacement but not much pressure on the spindle.

.