I do not concur that you should/must start out on grinding your own tooling, A bit like saying I should learn Morse code in case cell phones breakdown. Insert technology is not that difficult to understand and is widely used in both small and large machines with excellent results. They come in many shapes and sizes and also specialty ground tooling like the Micro100 stuff. To each their own.

Answering the posters question, and trying to keep this as simple as possible:

https://www.cutwel.co.uk/learn-the-turning-tool-iso-code-system

http://www.carbidedepot.com/formulas-insert-d.htm

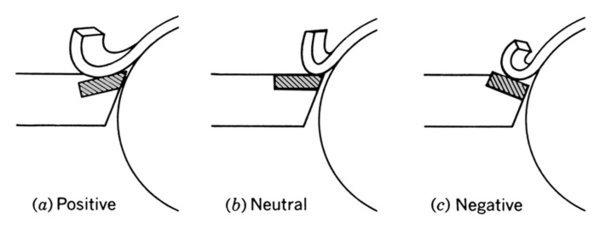

1. In general insert holders come in three different insert seat angular types, what is known as positive, neutral and negative rake. This is the angle of the insert relative to the horizontal cutting plane of the machine/perpendicular tangent of cut. With a positive rake the insert pocket tilts up, neutral has no tilt and negative the cutting insert tilts down in the seat. As one moves from positive to negative, it takes more Hp to cut, but there is increase insert durability, one can take deeper cuts and remove more material. Depending on insert seat angle, each require a different insert type due to the relief angle (clearance angle for the set pocket) at the cutting interface. Generally for lathes in the 2-5Hp range, neutral angle holders are used, a positive insert holder would be used on smaller lathes. With each holder there is a nomenclature that gives the specifications of the holder. If you are using an AXA style holders then the insert tooling will have a shank height of 1/2" unless you use an oversized holder that would accept say a 5/8" shank. The size of the holder usually dictated the size of the insert that can be used. So a 1/2" holder would typically use a 1/4" size insert, a 5/8" holder would use a 3/8" size insert, and 3/4"-1" holder would use a 1/2" size insert. But this can vary with holders.

View attachment 256594

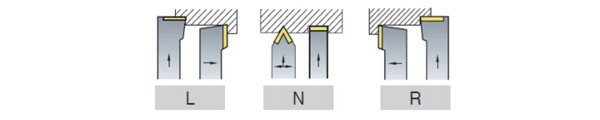

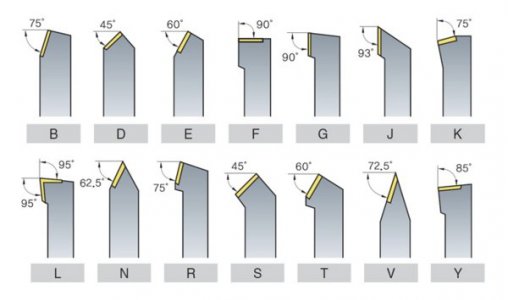

2. Inserts holders come in many styles or shapes, and the insert is held in place at many different angles relative to the cutting angle to the work in the horizontal plane. This allows different angles to be cut and profiling from different angles. In addition there holders are designed to cut right hand for cutting toward the headstock, center or neutral which can cut in either direction, left hand for cutting toward the tailstock. If you look at holders they indicate the axis of cutting in the horizontal plane. But holders come in many shapes and types.

View attachment 256596

View attachment 256597

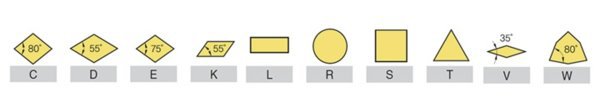

3. Inserts come in a zillion shapes, but for the most part there are a few shapes/styles of inserts that are most widely used in the hobbyist setting. Typically the most commonly used shape inserts are an 80 degree parallelogram, triangle, square, 55 degree parallelogram and trigon. Each one of these has a specific letter designation. Each has strengths and weaknesses. The triangular "T" insert was probably the most commonly used insert style, but this has been replaced by the 80 degree parallelogram "C" which is very durable. Different insert and holder styles are used based on the type or approach to your work and the cutting profile needed.

View attachment 256595

4, With each insert style there are characteristics that define the properties of that insert, such as size, how it is held, thickness, clearance angle, cutting tip size, chip breaker, etc. So it may seem there are an endless number of combinations and possibilities. But do not give up so quickly. In general for a specific holder, there is a specific style/insert designation that goes with that holder and just a few variables that you need to know. In addition there are inserts for specific materials, so the insert material, edge/chip breaker, coating, sharpness of the cutting edge or specific for the material. If you look at insert boxes they indicate the materials which that insert is optimized for. Some can be be used over a wide range of materials others are more narrow.

So lets look at what holders and inserts you would most likely be using. Given a 1/2" holder with neutral rake and an 80 degree parallelogram insert, then the appropriate insert for this holder would be a CC

MT style, the size insert would be either 1/4" (21.51) or 3/8" (32.51). The first number (2 vs. 3) defines the size of the insert, the last number defines the radius of the cutting tip (usually 1 or 2). The size insert depends on the tool holder. In addition you may get a right, center/neutral and left hand insert holder, and a boring bar (something like a 5/8 and 3/4") could also take the same insert size/style. Each holder gives you the insert characteristics. So try to standardize on a few insert styles, chose the holders sized for the size lathe and QCTP holders and inserts specific to the materials you are turning. I use CCMT style for most steels, cast iron, harder steel alloys, etc. On aluminum and softer materials I could use the same style with a different insert properties, so CC

GT which has a sharper ground edge as opposed to molded. The latter tend to be uncoated and be very shiny (polished surface).

My setup is 5/8" holders, 80 degree parallelogram insert CCMT/CCGT 32.51 or 2 for steel (CCGT for aluminum). My boring bars also take the same inserts. In addition I use 55 degree parallelogram insert DCMT/DCGT 32.51 or 2 (CCGT for aluminum) for getting in for narrow profiling. My go to setup for aluminum is WNMG inserts, I can handle these because I have the Hp, and also the insert style for aluminum requires less Hp. If you have under 2 Hp, then maybe consider a neutral rake triangle type insert. There is no Trigon holders in a neutral rake. With each style of holder I have settled on one insert that I typically use for steels/alloys and one that I use on aluminum (softer materials). I have attached some examples in the attached document. You can see the Iscar CCMT insert is basically rated for everything other than aluminum, and even with aluminum it turns acceptably. I use either a Cerazit or Korloy CCGT for aluminum but they can also used for say cast iron.

As a starter you can by a kit at a reasonable cost which will get you started with CCMT/CCGT holders, boring bars and inserts. A good starting point. Or you can can purchase more specific tool holders, some examples are in the attached document, they would need to be sized for your machine so most likely 1/2" holders, possibly 5/8" for some tooling if using an oversized holder.

http://www.precisionmatthews.com/sh...ool-set-sized-for-axa-quick-change-tool-post/

I have been turning for many years, and almost never needed to grind a specific cutter. It not a matter of time or being lazy, I do not have the space or setup to do so, nor want to waste my time doing so if there is another simpler technology that works as well or better. An insert can last me 4-6 months, if one breaks then I can replace it in a minute or two and continue my work with no change to my setup. The new insert will be exactly the same dimensionally. I get excellent surface finish in all kinds of materials and I am running about 50% of recommend SFM. If your lathe is not rigid enough or you cannot get the speeds up, then yes maybe HSS may be a better option.