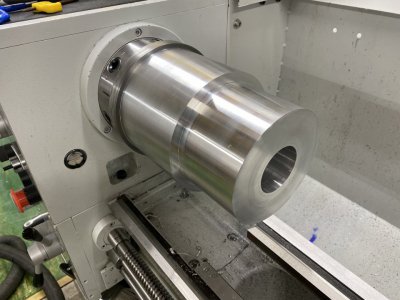

Got my D1-5 backplate taken care of. Fun little project all by itself.

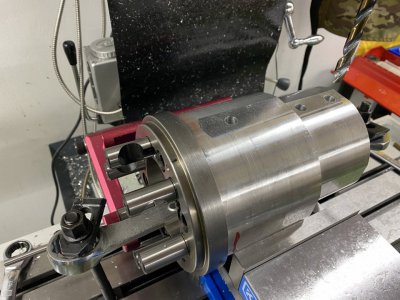

Now I'm thinking through how to keep the rest of the fixture as short and sweet as possible. I need to keep the first inch or so in tact at full diameter to account for the mounting bolts that join the two main pieces. I could put the rearward set of bolts through that section (with long ass bolts for a barrel fixture, heh) - Then taper the jig down after that.

I think that gives me everything I'm looking for. 7.25 inch overall length (vs an 11 inch two piece setup with a 4 jaw and inboard spider)

So for the old timers - am I doing anything stupid? Better way to skin a cat? Open to any suggestions.

Now I'm thinking through how to keep the rest of the fixture as short and sweet as possible. I need to keep the first inch or so in tact at full diameter to account for the mounting bolts that join the two main pieces. I could put the rearward set of bolts through that section (with long ass bolts for a barrel fixture, heh) - Then taper the jig down after that.

I think that gives me everything I'm looking for. 7.25 inch overall length (vs an 11 inch two piece setup with a 4 jaw and inboard spider)

So for the old timers - am I doing anything stupid? Better way to skin a cat? Open to any suggestions.