- Joined

- Mar 22, 2022

- Messages

- 342

Could end up as a "restore" or a "rebuild" if you stick to the proper definitions.

For now lets call it a discovery in process.

Few weeks back I purchased a well used Clausing 4900 as my first lathe. SN - 402215 looks to be around a 1967 build.

Link below was the starting point for the project. Got good advice and input on what I saw as the main problem area on the lathe.

https://www.hobby-machinist.com/threads/damage-assessment-help.103220/

Let the games begin

Cross slide screw assembly is on order from Clausing - shipped today.

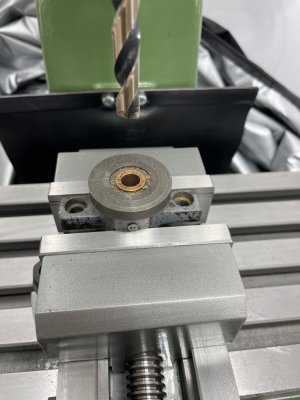

Two bronze bushings support the shaft in the assembly both have a fair amount of play. Some rough measurements and these look to be off the shelf parts. Will know more when my puller arrives later this week.

New belts coming with the screw assembly. Both were well worn, timing belt could be original.

Also needs new wiper felt and leveling pads are bolts

On power up and running prior to purchase there was tick and slight vibration needing to be tracked down.

The walk around and kick the tires, lift this push on that shows loose bushings on he apron hand wheel and far end of the lead screw

Lead screw shear pin needs replaced

With the belts and jackshaft removed the vibration when turning the spindle stopped. Tick is still there though.

One clunky bearing on the jackshaft and one very free spinning with no lube.

NOS Fafnir available on ebay $10 each

More to come, so far just minor wear and to be expected stuff but we have that ticking when tuning the spindle to chase down yet.

For now lets call it a discovery in process.

Few weeks back I purchased a well used Clausing 4900 as my first lathe. SN - 402215 looks to be around a 1967 build.

Link below was the starting point for the project. Got good advice and input on what I saw as the main problem area on the lathe.

https://www.hobby-machinist.com/threads/damage-assessment-help.103220/

Let the games begin

Cross slide screw assembly is on order from Clausing - shipped today.

Two bronze bushings support the shaft in the assembly both have a fair amount of play. Some rough measurements and these look to be off the shelf parts. Will know more when my puller arrives later this week.

New belts coming with the screw assembly. Both were well worn, timing belt could be original.

Also needs new wiper felt and leveling pads are bolts

On power up and running prior to purchase there was tick and slight vibration needing to be tracked down.

The walk around and kick the tires, lift this push on that shows loose bushings on he apron hand wheel and far end of the lead screw

Lead screw shear pin needs replaced

With the belts and jackshaft removed the vibration when turning the spindle stopped. Tick is still there though.

One clunky bearing on the jackshaft and one very free spinning with no lube.

NOS Fafnir available on ebay $10 each

More to come, so far just minor wear and to be expected stuff but we have that ticking when tuning the spindle to chase down yet.