- Joined

- Mar 22, 2022

- Messages

- 342

Thanks for popping in and following the refurb!I’ve enjoyed following your progress. Looking good. Do you have a plan as to when you want it useable by?

Sent from my iPhone using Tapatalk

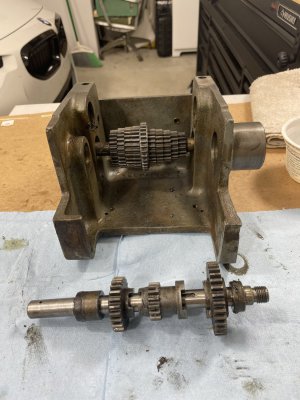

Progress has been crawling along as you may have noticed. When I bought the lathe the intent was to do some general cleanup and start using it.

Now it's becoming a platform to lean about disassembly, cleaning, painting and reassembly.

Don't really have a timeline so attempt to keep things moving forward as time permits.

Last edited: