- Joined

- Feb 2, 2013

- Messages

- 3,627

i purchased a set of inexpensive collet block's from all-industrial tool supply for use in my lathe and milling machines.

they were shipped fast and are very nicely finished, better than i thought i might get for the price.

i don't have any connection to the company, but i had a good experience and thought i'd say something about it.

the set came with 2 spanner nuts and a lever/cam closer, but didn't include the spanner wrench.

(the wrench was not pictured in the ebay store nor was reference made to the spanner wrench in the ebay store)

i didn't consider the wrench to be a deal breaker, the overall cost was under $50 shipped- i let it go.

my decision worked out for awhile, i used the lever/cam closer and was happy as a clam.

then i wanted to hold some 1" stock that was slightly under 1", .988" to be exact.

but there's another hitch, i needed a longer piece to pass through the collet and block for milling in the vise.

i figured i'd spring the 1" 5C collet a little and grip the material,

i didn't have the spanner.

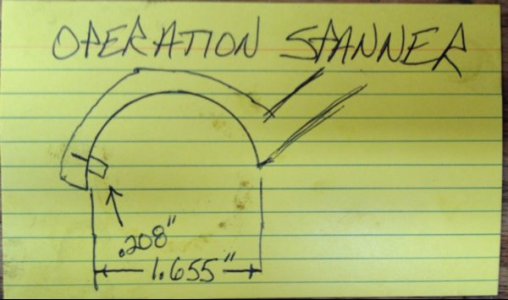

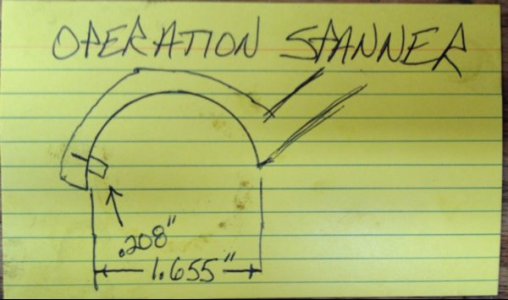

so my project was to make a spanner.

i had some 2-1/2" 1018, and some 5/8 rod and some rod material for the pins

it was just as simple to make 2 at the same time, so i did!

i punched the center out to 1" and finished bored to 1.70" with a freshly resharpened cemented carbide boring bar

i cut the ring in half and shortened the halves by gang milling in the vertical mill

i had some 5/8" 304 shafting reclaimed from a machine,

and a piece of 5/8 hot rolled unknowinium- that didn't want to machine very well with carbide, so i switched to HSS

and it machined a bit better but was some pretty tough stuff

i made some pins from some hot rolled 3/16" stock and cut them at .345" long

i center drilled and tapped the newly formed handles to 1/4"-20, and drilled and tapped the wrench head to attach the handles

i drilled the pin holes undersize and reamed to .1870"- the pin has a light press fit.

i cut 1/4"-20 all thread studs and attached the wrench heads to the handles and used red locktite to bind the heads to the handles

and made final assessments

i swept the angle of the handle away from the flat plane to potentially save a knuckle or 2

they passed inspection

i took one for a test ride....

and the final shot

now i can go back and attempt to finish the project i originally set out to do.

it never seems to end.

make something to make something else work , or otherwise take another step forward on another project!

thanks for reading!!!

they were shipped fast and are very nicely finished, better than i thought i might get for the price.

i don't have any connection to the company, but i had a good experience and thought i'd say something about it.

the set came with 2 spanner nuts and a lever/cam closer, but didn't include the spanner wrench.

(the wrench was not pictured in the ebay store nor was reference made to the spanner wrench in the ebay store)

i didn't consider the wrench to be a deal breaker, the overall cost was under $50 shipped- i let it go.

my decision worked out for awhile, i used the lever/cam closer and was happy as a clam.

then i wanted to hold some 1" stock that was slightly under 1", .988" to be exact.

but there's another hitch, i needed a longer piece to pass through the collet and block for milling in the vise.

i figured i'd spring the 1" 5C collet a little and grip the material,

i didn't have the spanner.

so my project was to make a spanner.

i had some 2-1/2" 1018, and some 5/8 rod and some rod material for the pins

it was just as simple to make 2 at the same time, so i did!

i punched the center out to 1" and finished bored to 1.70" with a freshly resharpened cemented carbide boring bar

i cut the ring in half and shortened the halves by gang milling in the vertical mill

i had some 5/8" 304 shafting reclaimed from a machine,

and a piece of 5/8 hot rolled unknowinium- that didn't want to machine very well with carbide, so i switched to HSS

and it machined a bit better but was some pretty tough stuff

i made some pins from some hot rolled 3/16" stock and cut them at .345" long

i center drilled and tapped the newly formed handles to 1/4"-20, and drilled and tapped the wrench head to attach the handles

i drilled the pin holes undersize and reamed to .1870"- the pin has a light press fit.

i cut 1/4"-20 all thread studs and attached the wrench heads to the handles and used red locktite to bind the heads to the handles

and made final assessments

i swept the angle of the handle away from the flat plane to potentially save a knuckle or 2

they passed inspection

i took one for a test ride....

and the final shot

now i can go back and attempt to finish the project i originally set out to do.

it never seems to end.

make something to make something else work , or otherwise take another step forward on another project!

thanks for reading!!!

Last edited: