Hello Mike,

This is a start... I think that this is what you were looking for...

This is the method that I used to test it. Is this correct ?

I don't have a handle on all of the jargon and I don't understand the interrupt relays... ?

I have company coming for supper, so I'll have to leave this until tomorrow morning...

Brian

Hi Brian,

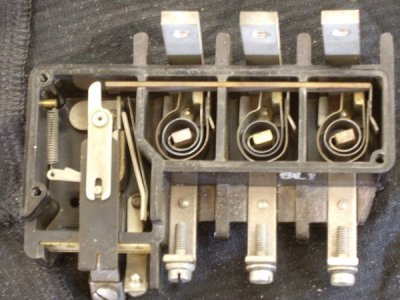

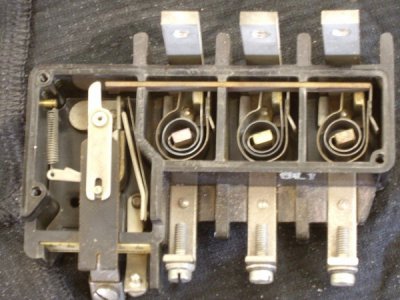

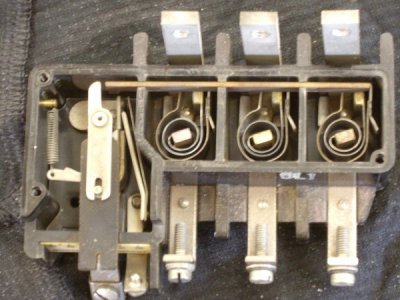

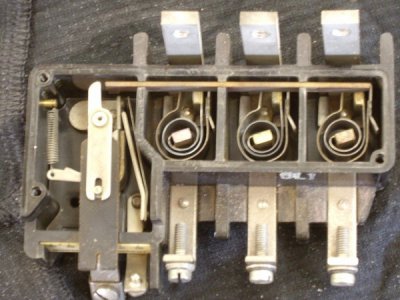

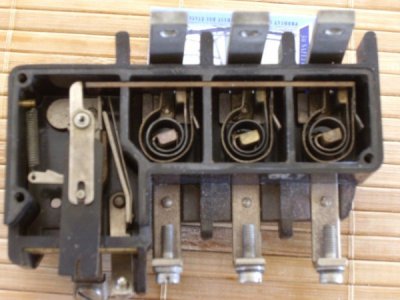

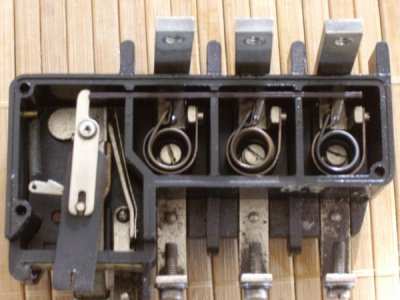

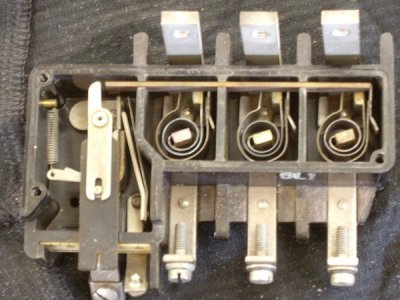

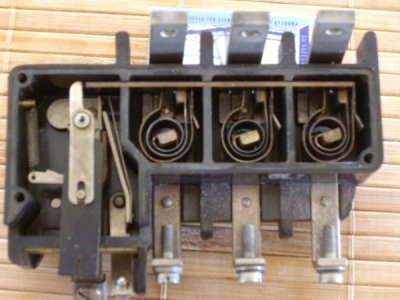

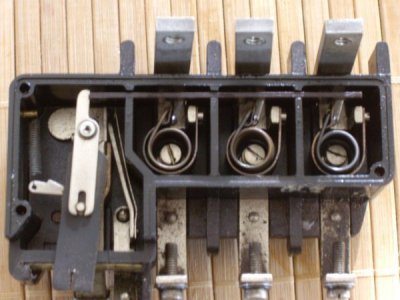

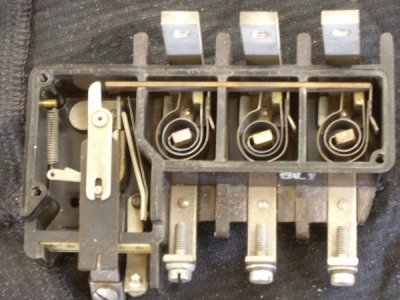

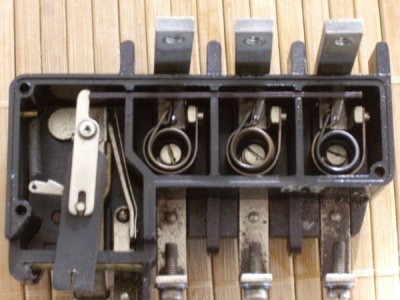

that is an OL relay, yes sir!!!

I don't like the looks of the heater coil on the right side, if you look at the heater coil the inner coil appears to be touching the outer coil or are very close to touching and could be a factor in the shut down condition.:thinking:

(i'm assuming you have already disconnected power to the mill)

I am curious also to look inside the little box situated below this OL relay, the one labeled " Danger live Terminals".

if you disconnect the power from the milling machine to the RPC you won't be in danger to remove the cover mentioned above that conceals the guts of the larger black box. there appears to be a dial or knob missing- that throws up a red flag for me...

Yes Brian, you will test each terminal exactly as pictured on the Rx1 setting(lowest ohm setting for low resistance circuits). you should read very little resistance or no resistance dependent on the sensitivity of your meter on each set of terminals.

the interrupt circuit is the 2 smaller terminals pictured on the left side of the OL relay.

by putting a meter leads on both of the smaller stacked screw terminals and setting the Ohm meter to Rx1(lowest setting) you can test the interrupt. the interrupt should be a normally closed switch thus there should be little or no resistance measured dependent on the sensitivity of the meter.

if this switch should happen to be open, it would need repair or replacement- it is not functioning correctly.

i'll try not to use too many technical electricalisms , let me know if i'm confusing you and i'll take it down a notch.

i make the constant mistake of thinking that others know what i know,:banghead:

(not always a good thing- there are a lot smarter people than I)

mike

)