- Joined

- Feb 23, 2016

- Messages

- 424

Excellent points, @Jim F and @Geswearf.

I did my first cut, just because I couldn't stand the wait, and have lots of questions. But let's take things in order. Have aligned ("leveled") the lathe. I watched Blondiehacks' and TOT's videos on taking the twist out, and just wanted to see if what I am doing is legit or not. So I used two 1-2-3 blocks and placed them on the flat ground track of the bed ("ways" maybe) near the head stock. Then adjusted the feet until the machinist level read center. Switched the block, in case they are mismatched; also flipped the level, so did 4 observations Repeated near the tail stock.

In those videos they also cut a cylinder like a bar bell to see if the diameters at the ends agree. I am not quite ready for that, but once my tools are set up etc will do that with a 0.75" steel rod (I only have a 0-1" micrometer).

Next have to figure out a way to center the tool height. I saw on YT that people have fancy indicator-based tools, but for starts I just eyeballed it to the tail stock.

Is there any better simple way?

Feeds and speeds.

I am familiar from milling with calculating feeds and speeds and with my mill I do not use carbide tools because of my max spindle speed of 4200; so am familiar with the 80 SFPM rate for a HSS cutter in steel. Today my first ever cut was to face a 2.75" diameter aluminum scrap, for which the RPM calculation is (2800 / 2.75) x 3.82 = 3900RPM. That seems insanely fast; obviously the lathe tops out at 2,000 but I felt uncomfortable even with that, and used 800 SFPM and 1000RPM. Even that felt fast, but the surface finish seemed good. Will check Machinery's Handbook for feed rates. LMS' calculator suggests 1000 SFPM for carbide and yields 37ipm feed rate.

Chips seem crazy. I though you are supposed to have small comma-shaped ones:

I have lots of questions; will also have to install the DRO properly, and learn to use it, and think about tooling storage (3D printed most likely).

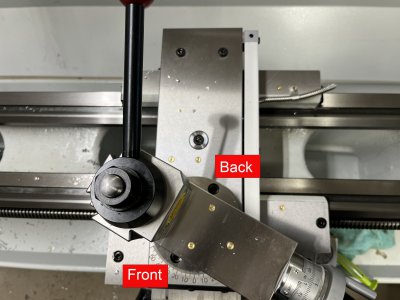

Seems like the compound has a default screw position at 30degrees, and could not figure out how to tighten it at other degrees. 30 degrees will work, but I wonder if I'm missing something obvious.

The lathe is a delight to use. Feels like a quality item, tight, and smooth.

HAPPY NEW YEAR EVERYONE!

I did my first cut, just because I couldn't stand the wait, and have lots of questions. But let's take things in order. Have aligned ("leveled") the lathe. I watched Blondiehacks' and TOT's videos on taking the twist out, and just wanted to see if what I am doing is legit or not. So I used two 1-2-3 blocks and placed them on the flat ground track of the bed ("ways" maybe) near the head stock. Then adjusted the feet until the machinist level read center. Switched the block, in case they are mismatched; also flipped the level, so did 4 observations Repeated near the tail stock.

In those videos they also cut a cylinder like a bar bell to see if the diameters at the ends agree. I am not quite ready for that, but once my tools are set up etc will do that with a 0.75" steel rod (I only have a 0-1" micrometer).

Next have to figure out a way to center the tool height. I saw on YT that people have fancy indicator-based tools, but for starts I just eyeballed it to the tail stock.

Is there any better simple way?

Feeds and speeds.

I am familiar from milling with calculating feeds and speeds and with my mill I do not use carbide tools because of my max spindle speed of 4200; so am familiar with the 80 SFPM rate for a HSS cutter in steel. Today my first ever cut was to face a 2.75" diameter aluminum scrap, for which the RPM calculation is (2800 / 2.75) x 3.82 = 3900RPM. That seems insanely fast; obviously the lathe tops out at 2,000 but I felt uncomfortable even with that, and used 800 SFPM and 1000RPM. Even that felt fast, but the surface finish seemed good. Will check Machinery's Handbook for feed rates. LMS' calculator suggests 1000 SFPM for carbide and yields 37ipm feed rate.

Chips seem crazy. I though you are supposed to have small comma-shaped ones:

I have lots of questions; will also have to install the DRO properly, and learn to use it, and think about tooling storage (3D printed most likely).

Seems like the compound has a default screw position at 30degrees, and could not figure out how to tighten it at other degrees. 30 degrees will work, but I wonder if I'm missing something obvious.

The lathe is a delight to use. Feels like a quality item, tight, and smooth.

HAPPY NEW YEAR EVERYONE!

Last edited: