-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Disappointed in abilities with 12" Logan

- Thread starter Investigator

- Start date

- Joined

- Mar 11, 2016

- Messages

- 14

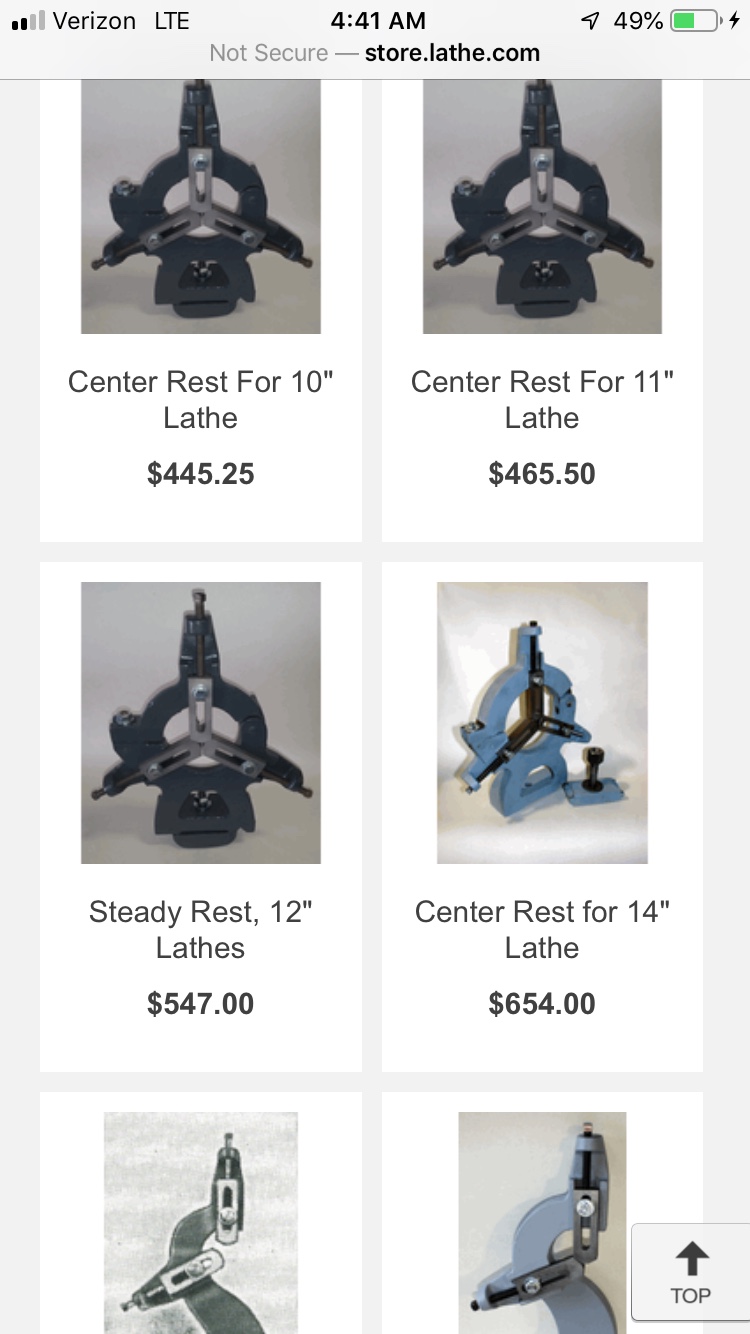

Damn. Those steady rests cost more than I paid for my whole model 200, and that came with a steady and a follower.

Sent from my iPhone using Tapatalk

- Joined

- Dec 25, 2011

- Messages

- 10,511

Joe,

If you paid less than $150 for a complete working 200 with both steady and follower rests, then you either stole it or bought it 40 or 50 years ago. If the former, I wouldn't be spreading that fact around.

If you paid less than $150 for a complete working 200 with both steady and follower rests, then you either stole it or bought it 40 or 50 years ago. If the former, I wouldn't be spreading that fact around.

- Joined

- Mar 11, 2016

- Messages

- 14

Joe,

If you paid less than $150 for a complete working 200 with both steady and follower rests, then you either stole it or bought it 40 or 50 years ago. If the former, I wouldn't be spreading that fact around.

My point is Before I would pay $500 or $600 something for a steady rest alone, I would spend $600-$700 for an old Logan that came with one. That’s just what I did a few years ago when I bought my 200. I never used the steady rest or the follower in my little basement shop, but it’s there if I need it.

The prices on that link are ridiculous. I don’t know where you saw $150.

Old iron is cheap in my neck of the woods, often with a bunch of tooling. Machine shops are closing every week in the surrounding area of NYC, due to ridiculous rents and absurd property value spikes. Come here for a month with a container truck, and you could load it up and resell the stuff all across the country where tractors are cheap and plentiful but machine tools are scarce.

Sent from my iPhone using Tapatalk

10" LOGAN LATHE STEADY REST | eBay

Used 10" Logan lathe steady rest. One obvious brass brazed repair, but otherwise in good shape.

rover.ebay.com

- Joined

- Dec 27, 2014

- Messages

- 4,056

Did I read that he's using a turret lathe? What tailstock? What Steady Rest? The bearing mounted spider is the only way to go.

- Joined

- Jun 8, 2016

- Messages

- 603

140.00

10" LOGAN LATHE STEADY REST | eBay

Used 10" Logan lathe steady rest. One obvious brass brazed repair, but otherwise in good shape.rover.ebay.com

Did I read that he's using a turret lathe? What tailstock? What Steady Rest? The bearing mounted spider is the only way to go.

I made a steady rest from a piece of 1.5" thick aluminum plate. Cut a 3" through hole with a hole saw, and used my mill to make slots 120* apart for brass fingers. It's not the prettiest thing, but it works.

I’m glad you have something that’s working. Good steady rests don’t come cheap, and that’s when you can find one. I run into the same problems with my Clausing lathe. Rests go for a fortune. Anyway, I posted the link because I was looked for a rest for my lathe. I just happened to see a Logan rest.

- Joined

- Jun 8, 2016

- Messages

- 603