- Joined

- Oct 31, 2016

- Messages

- 2,649

I have a craftsman 12x36 lathe. Spindle bore is 25/32. I have often wondered if I could bore it to a larger size. And if so, how much could you go. There is a guy who goes by Varmint Al who bored out his HF mini lathe from .808 to 13/16. http://www.varmintal.com/alath.htm This is what got me wondering about boring the spindle on my lathe.

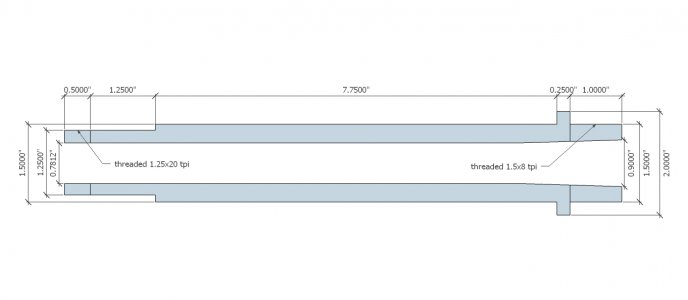

The tailstock end of the spindle on my lathe has 1.25x 20 threads. The minor diameter is 1.1905. Subtracting 25/32 leaves a wall thickness of .205. Going to a 13/16 bore would leave a wall thickness of .189. A 7/8 bore would leave a wall thickness of .158. That is probably the biggest that I could go. What would be the minimum wall thickness that you could have without sacrificing the strength of the spindle.

I know. Just buy a bigger lathe. That isn't going to happen.

The tailstock end of the spindle on my lathe has 1.25x 20 threads. The minor diameter is 1.1905. Subtracting 25/32 leaves a wall thickness of .205. Going to a 13/16 bore would leave a wall thickness of .189. A 7/8 bore would leave a wall thickness of .158. That is probably the biggest that I could go. What would be the minimum wall thickness that you could have without sacrificing the strength of the spindle.

I know. Just buy a bigger lathe. That isn't going to happen.