- Joined

- Feb 8, 2014

- Messages

- 11,144

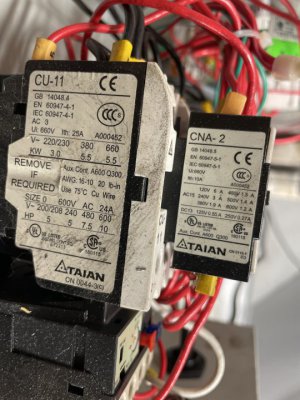

I would not expect to find any 120VAC in that system. The main power is 240VAC and the control power is 24VAC. In reading your first post it would seem that everything is working normally. If all the functions work as they should, then I think you are OK. The only thing that I would concern myself with is that the machine is properly grounded.