- Joined

- Aug 11, 2022

- Messages

- 46

I re acquired a lathe I bought new in 2000. It came back as a gift. It was never used and stayed in storage until I got it back a couple months ago.

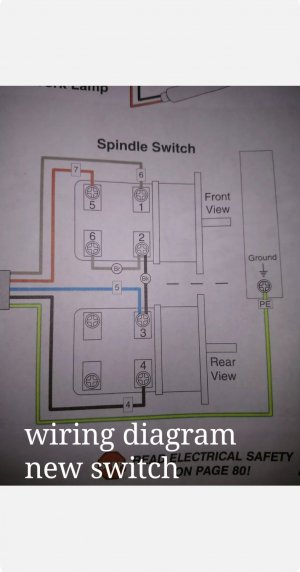

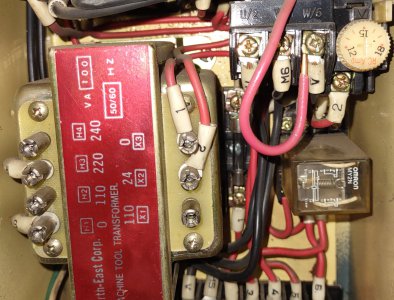

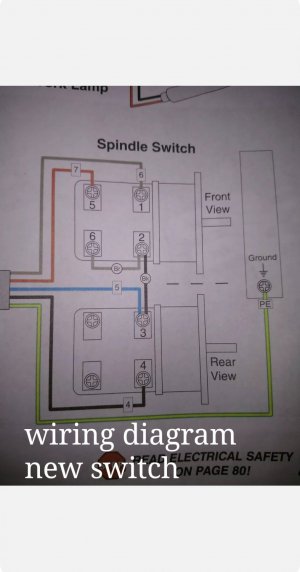

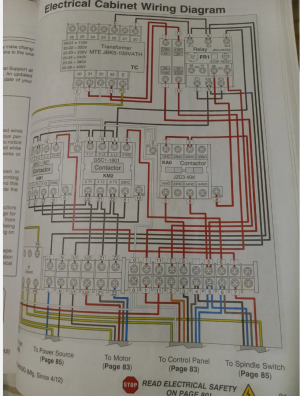

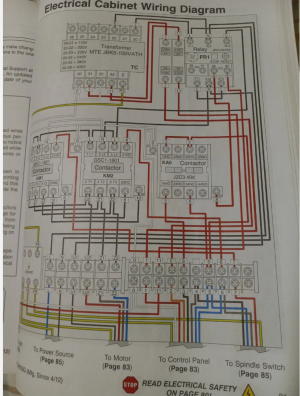

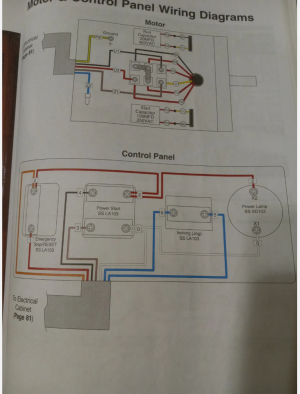

I changed the transformer out and the temporary switches work but the other lever did not. I purchased a new switch but of course it's different.

I am at my a loss.

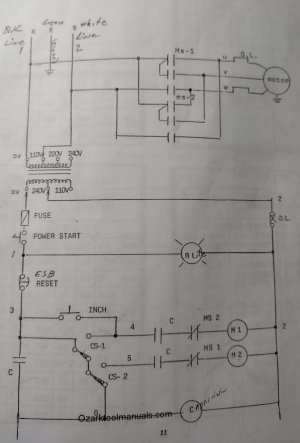

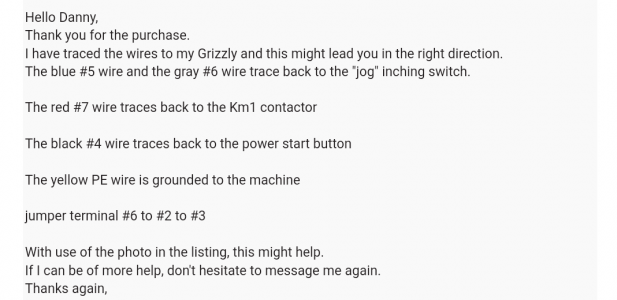

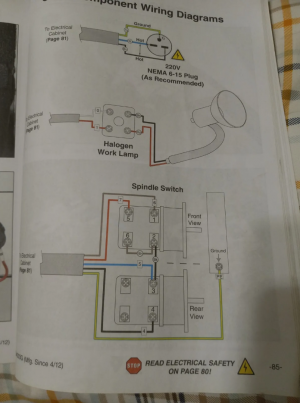

The attached photos show the old switch and there are some diagrams I've gotten as help but I'm still confused.

Any help is greatly appreciated.

Thanks Danny

I changed the transformer out and the temporary switches work but the other lever did not. I purchased a new switch but of course it's different.

I am at my a loss.

The attached photos show the old switch and there are some diagrams I've gotten as help but I'm still confused.

Any help is greatly appreciated.

Thanks Danny