- Joined

- Apr 30, 2015

- Messages

- 11,313

But you have an Enco correct? Is the front panel the same as the G4003? Show me a pic of your front panel

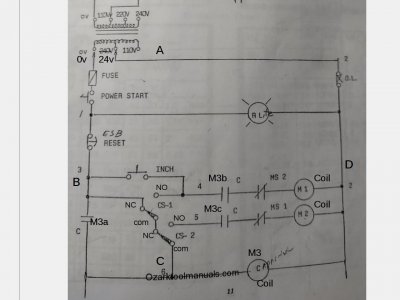

Where did you buy the new switch from? Amazon? What is the full part #? I can see HZ5B-10/2 and there should be some digits after that-

We need to verify the internal contacts of the new switch somehow.

BTW have you checked to see that the new switch will mount up the same as the old one? Mounting holes and shaft size the same?

If not I would hold off on modifying the machine until we verify the switch internals

Would you be willing to re-purpose the inching/jog button? There may be a way we could make the new switch work

with a slight re-wire but we would need to change the inching button into an "enable" button

Where did you buy the new switch from? Amazon? What is the full part #? I can see HZ5B-10/2 and there should be some digits after that-

We need to verify the internal contacts of the new switch somehow.

BTW have you checked to see that the new switch will mount up the same as the old one? Mounting holes and shaft size the same?

If not I would hold off on modifying the machine until we verify the switch internals

Would you be willing to re-purpose the inching/jog button? There may be a way we could make the new switch work

with a slight re-wire but we would need to change the inching button into an "enable" button

Last edited: