- Joined

- Oct 17, 2018

- Messages

- 922

I have a 4.5" dia x 0.25" thick steel (type unknown, but it's nothing fancy) pipe I'd like to square the end on. I cut it with a reciprocating saw so it's a bit crooked. I grinded it down a bit. My question is how I should go about squaring it up on the lathe?

Here it is mounted on the chuck. You can see where I've tried to cut it:

Here is the cutter I'm attempting to use. It's cut like a cut-off tool:

I thought I might try using this cutter in this orientation when I get the end smoother:

Here is an end-view of the pipe:

I'm getting lots of chatter. The lathe is on low speed (164/500) on the spindles and medium speed (1140) on the motor. Back gear is not engaged. If the motor I have is similar to the original and I'm using the speed chart in the MOLO correctly, then I'm at 500 RPM. I tried it on low (164) and it really chattered. Higher speed gave a smoother cut.

Cutting speed for carbon steel is 80 ft/min. 3.82x80/4.5=67.91 RPM. I'd use the back gear drive for that speed, correct?

Because the end is crooked and the pipe wobbles a bit in the chuck, the cutter will contact the material, then be in the air, then contact the material, on so on. I've grinded it such that the tool doesn't contact a blunt end; instead, it contacts a "ramp"/inclined surface, but at some point, the cutter will break thru; then what? Whenever I've used a parting tool before, I've always stopped before it broke thru. I may not have that option here; it may break thru in one part.

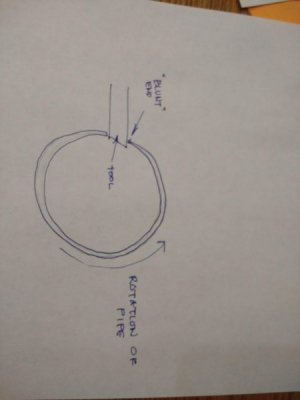

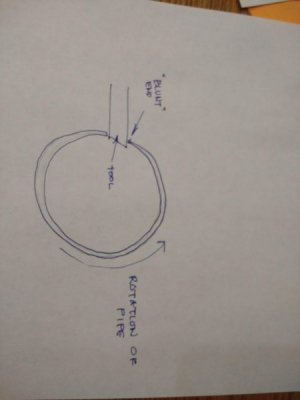

Here's a sketch to illustrate what I'm talking about:

One option may be to grind this down as square as I can, then finish it on the lathe. However, it's a lot of grinding. I thought using a cut-off type tool would be quicker and look nicer. I didn't count on the pipe wobbling, either, but didn't think that would matter since I don't need the end perfect, just somewhat smooth and straight.

I'd like some guidance on how to safely do this. Thanks!

Here it is mounted on the chuck. You can see where I've tried to cut it:

Here is the cutter I'm attempting to use. It's cut like a cut-off tool:

I thought I might try using this cutter in this orientation when I get the end smoother:

Here is an end-view of the pipe:

I'm getting lots of chatter. The lathe is on low speed (164/500) on the spindles and medium speed (1140) on the motor. Back gear is not engaged. If the motor I have is similar to the original and I'm using the speed chart in the MOLO correctly, then I'm at 500 RPM. I tried it on low (164) and it really chattered. Higher speed gave a smoother cut.

Cutting speed for carbon steel is 80 ft/min. 3.82x80/4.5=67.91 RPM. I'd use the back gear drive for that speed, correct?

Because the end is crooked and the pipe wobbles a bit in the chuck, the cutter will contact the material, then be in the air, then contact the material, on so on. I've grinded it such that the tool doesn't contact a blunt end; instead, it contacts a "ramp"/inclined surface, but at some point, the cutter will break thru; then what? Whenever I've used a parting tool before, I've always stopped before it broke thru. I may not have that option here; it may break thru in one part.

Here's a sketch to illustrate what I'm talking about:

One option may be to grind this down as square as I can, then finish it on the lathe. However, it's a lot of grinding. I thought using a cut-off type tool would be quicker and look nicer. I didn't count on the pipe wobbling, either, but didn't think that would matter since I don't need the end perfect, just somewhat smooth and straight.

I'd like some guidance on how to safely do this. Thanks!