- Joined

- Sep 28, 2013

- Messages

- 4,308

1. That's what I thought. Is there a rule about how far out something can stick before it's considered too long?

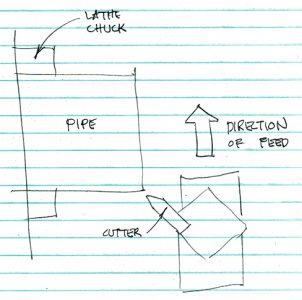

you'll hear it - the work or cutter (or both!) will sing, even with light cuts. Lots of chatter and squealing. To be honest, it'll be a fairly miserable job and take you a while, but as long as you take your time and don't try any short cuts you'll get it done just fine.