- Joined

- Mar 21, 2018

- Messages

- 1,600

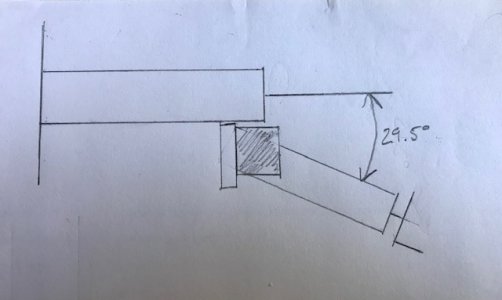

I respectfully disagree. If the compound angle is set to more than 30 degrees from perpendicular to the spindle axis, it will definitely affect the shape and finish of the thread.

Okay, I'll concede your point and say that only the portion of the cut of the last pass will have a 60º included angle. But I would also say that for any angle on the compound greater than 30º (for a 60º thread) that you aren't cutting a thread.