-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Found a “deal” on the local facebook

- Thread starter D.sebens

- Start date

- Joined

- Oct 11, 2016

- Messages

- 3,870

@D.sebens The Hartford mill is a good piece of kit. I have one. They are Taiwanese made.

The SouthBend surface grinder appears to be an automatic. Nice machine.

The Hardinge mill has a good name, and is hobby sized. Someone will pick it up for $1000 or 800$ or so quite easily.

The other surface grinder seems a little incomplete, Do you know what brand it is? You should be able to sell it as a 'bargoon' for 400$ or so. If it runs, and quietly, then $800-1000 in the condition (dirty) that it is in.

The SG will need a rotary converter, as it has at least 2 motors, and doing the VFD thing for both becomes a little silly. If you are going to keep the Hartford and the SouthBend SG, you are way better off with a rotary phase converter. Around 7 HP will do. 5Hp will start the mill or the SG, but having a little headroom won't hurt. If you are budget minded, even a 3HP will work, but the SG will have to have the pump motor turned off when starting the spindle - not a good thing to have to remember... Minimum I'd go with 5HP.

The SouthBend surface grinder appears to be an automatic. Nice machine.

The Hardinge mill has a good name, and is hobby sized. Someone will pick it up for $1000 or 800$ or so quite easily.

The other surface grinder seems a little incomplete, Do you know what brand it is? You should be able to sell it as a 'bargoon' for 400$ or so. If it runs, and quietly, then $800-1000 in the condition (dirty) that it is in.

The SG will need a rotary converter, as it has at least 2 motors, and doing the VFD thing for both becomes a little silly. If you are going to keep the Hartford and the SouthBend SG, you are way better off with a rotary phase converter. Around 7 HP will do. 5Hp will start the mill or the SG, but having a little headroom won't hurt. If you are budget minded, even a 3HP will work, but the SG will have to have the pump motor turned off when starting the spindle - not a good thing to have to remember... Minimum I'd go with 5HP.

- Joined

- Dec 2, 2012

- Messages

- 1,733

lol. Side note. What am I looking at dollar wise for a dro fit and a 3ph converter? I assume I would want a vfd? They make all in one vfd’s right? Also what about it being in a unconditioned shed. Would a heavy oiling and a cover in the winter protect it from condensation?

I use painters dust sheets and the only rust issues i've had this winter (in merky UK world) was a bit of light rust on a hand wheel from condensation (and being a bit to bizzy to use it regular of late.).

Lots of oil does wonders

Stu

- Joined

- Mar 27, 2022

- Messages

- 426

So I am getting these this weekend. I plan on 4 straps per machine. The two grinders and the horizontal mill seem straight forwards. Any tips for the hartford bp clone?

I also am going to screw wood boards around the perimeter of the bases

I also am going to screw wood boards around the perimeter of the bases

- Joined

- Aug 13, 2020

- Messages

- 1,342

Drop the knee as low as possible. Rotate the head to lower it as much as possible, or lift the ram off the column and carry it separately. Bolting the base to 4x4 to widen the stance is also a good option.

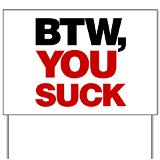

And I'd like to be the first to say:

You SUCK!!

And I'd like to be the first to say:

You SUCK!!

- Joined

- Jan 7, 2016

- Messages

- 3,289

Take your time and be careful. You have not mentioned what type of equipment you have to move them or the type of transport (trailer/truck).So I am getting these this weekend. I plan on 4 straps per machine. The two grinders and the horizontal mill seem straight forwards. Any tips for the hartford bp clone?

I also am going to screw wood boards around the perimeter of the bases

Although the machines will need some TLC, I think that you did exceptionally well on this purchase.

Oh....

- Joined

- Mar 27, 2022

- Messages

- 426

Truck and trailer. Trailer is rated for the load. I’m having my dad come too. He ran commercial semis for years. I hate the feeling when you say “That ain’t going anywhere” then down the road you realize that it is in fact trying to go somewhere!

- Joined

- Mar 27, 2022

- Messages

- 426

Estimating weights, what would you say the weight of the surface grinders are? I’ve got a trailer that can handle 9k payload and a 3 axle deckover that can handle much more. I can take the deckover but would rather take the smaller trailer. The smaller trailer is plenty long.