- Joined

- Feb 8, 2014

- Messages

- 11,144

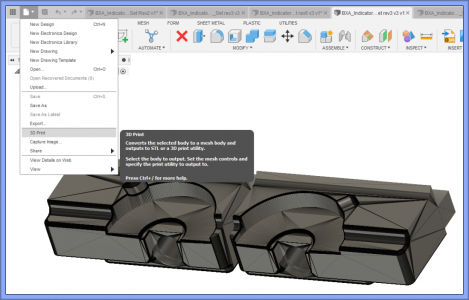

I downloaded the original file from Thingverse. Imported it into Fusion, it came in as metric and is about 36'' long.

I scaled it by 0.1 and it seems to be about right in inches.

I then exported it as a .f3d file and brought it back in, the scaling seems to be correct. This should have removed any of the original scaling.

I then exported that as a .stl file, and brought that back in, the scaling was back to a 36'' part.

It seems that the .stl export/import somehow changes the scaling.

I'm going to go have a chat with my son, he's the expert in Fusion. He's in the shop, so I'll post back in a few minutes.

I scaled it by 0.1 and it seems to be about right in inches.

I then exported it as a .f3d file and brought it back in, the scaling seems to be correct. This should have removed any of the original scaling.

I then exported that as a .stl file, and brought that back in, the scaling was back to a 36'' part.

It seems that the .stl export/import somehow changes the scaling.

I'm going to go have a chat with my son, he's the expert in Fusion. He's in the shop, so I'll post back in a few minutes.