-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

G0773 Lathe / Mill Combo

- Thread starter BROCKWOOD

- Start date

I have loved using 6061 in 1/8" plate for making flat panels. Once I saw that it wouldn't bend to my desired shape, I ordered up a sheet of 3003 in 1/16" sheet. I knew I wanted the edges to be rounded, so, though this is a shapeable aluminum, I had my work cut out for me. I began with a piece of paper to see what a corner cut line might look like.

I can't even get it to turn out right in paper. So, I've ordered up some quarter round aluminum extrusions. This should postpone my foray into how to hammer out a Ferrari GTO body. More importantly, this should get me my lathe running much sooner.

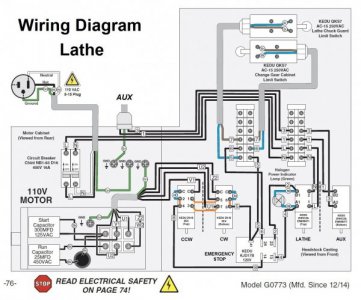

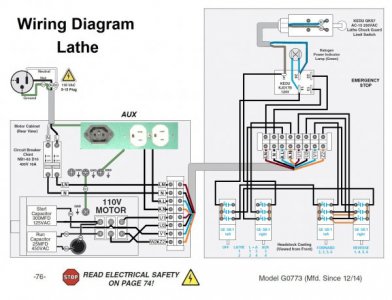

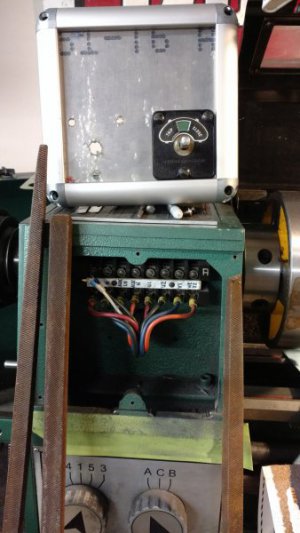

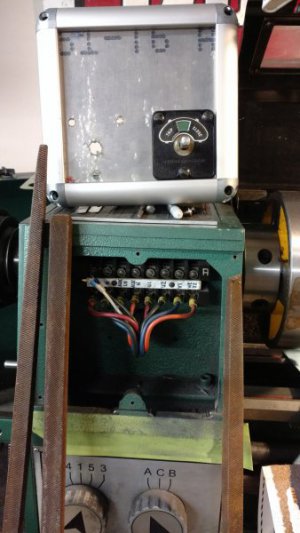

Back to waiting on parts, but staying busy with prep work. Only the front panel & wiring remains. All the wiring in every other part is complete & buttoned up. I rounded out the 2 bottom corners & retired the gear cover safety switch. I will keep the chuck cover safety switch in use. That's the 2 wires sticking up out of the power / motor bus. The Emergency Stop will now kill the Lathe (as it always did) & the Aux too once wiring is complete.

SB-1 switches sometimes called for a factory jumper. I decided to make some out of brass. Factory jumpers are in the background.

Clickspring makes shaping brass look easy. Well, I am doing 4 at once. I'm also working up the schematic of the as finished changes. Keeping busy & having fun getting there!

In other news, Grizzly has dropped the G0773 from their 2019 catalog. Their latest combo is based on the 4003 series. It uses 240V single phase & the mill no longer has the left / right column tilt debacle (feature). My mill portion will get upgrades at some point - but that is a story for another time.

I can't even get it to turn out right in paper. So, I've ordered up some quarter round aluminum extrusions. This should postpone my foray into how to hammer out a Ferrari GTO body. More importantly, this should get me my lathe running much sooner.

Back to waiting on parts, but staying busy with prep work. Only the front panel & wiring remains. All the wiring in every other part is complete & buttoned up. I rounded out the 2 bottom corners & retired the gear cover safety switch. I will keep the chuck cover safety switch in use. That's the 2 wires sticking up out of the power / motor bus. The Emergency Stop will now kill the Lathe (as it always did) & the Aux too once wiring is complete.

SB-1 switches sometimes called for a factory jumper. I decided to make some out of brass. Factory jumpers are in the background.

Clickspring makes shaping brass look easy. Well, I am doing 4 at once. I'm also working up the schematic of the as finished changes. Keeping busy & having fun getting there!

In other news, Grizzly has dropped the G0773 from their 2019 catalog. Their latest combo is based on the 4003 series. It uses 240V single phase & the mill no longer has the left / right column tilt debacle (feature). My mill portion will get upgrades at some point - but that is a story for another time.

Well, with these big ol switches, I needed more mounting space. A little jigsaw, a little Dremel & some big files!

Could have just made it all fit, but prefer making it as professional as we had in the old days! & yes, I am slow on account of my tools are slow but steady! Hey, helps me regain my strength in measured steps.

Lots of filing & shaping left - but getting there & as always, just glad for progress at this point in the game!

Could have just made it all fit, but prefer making it as professional as we had in the old days! & yes, I am slow on account of my tools are slow but steady! Hey, helps me regain my strength in measured steps.

Lots of filing & shaping left - but getting there & as always, just glad for progress at this point in the game!

Last edited:

My favorite part about this site is how we all take the label "Hobby" as a good thing! I don't have the time constraint weighing on me. No constant compromise between finish the job & quality. Plus, this only gets to happen when all else is done for the day.

When we left off 3 weeks ago, the front panel fit as designed & it was time to just finish connecting the wiring. Well, it didn't go that easily. After adding just a few wires to the front panel, I decided to check fitment to the lathe. No Go. I had to cut an additional 1/2" out of the lower lip.

Now the loom is complete with my 1st ever old school wax string wrap (think pre zip ties).

The safety switch (for the chuck cover) wiring is too short. It turned out to be 16 gauge, so an upgrade had to happen. Having never found a replacement that I thought ideal, it was time to see what could be done with what I have.

Just like all the ones I've found on line, there is a NO & a NC contact. Stock is the lower of the 2 in the pic. I've converted the top one to 2 NC contacts, removed a ribbing on the perimeter center & am making brass jumpers. This will bump the amp rating to 24 & the wiring will be 12 gauge. Slow but steady & making progress. It's a pleasure to do this work without a time clock! I also need to grind out the right corner in the last pic. The wiring loom needs a place to bend onto it's final approach at the terminal block on the chassis (behind the paper towel). It's designed to just pull the front cover away & flip it upside down to rest on top for disconnection & servicing. Cool thing is when you design this much fortitude into a product & also plan ahead for servicing: The need for servicing goes away!!!!!!!!!!!

When we left off 3 weeks ago, the front panel fit as designed & it was time to just finish connecting the wiring. Well, it didn't go that easily. After adding just a few wires to the front panel, I decided to check fitment to the lathe. No Go. I had to cut an additional 1/2" out of the lower lip.

Now the loom is complete with my 1st ever old school wax string wrap (think pre zip ties).

The safety switch (for the chuck cover) wiring is too short. It turned out to be 16 gauge, so an upgrade had to happen. Having never found a replacement that I thought ideal, it was time to see what could be done with what I have.

Just like all the ones I've found on line, there is a NO & a NC contact. Stock is the lower of the 2 in the pic. I've converted the top one to 2 NC contacts, removed a ribbing on the perimeter center & am making brass jumpers. This will bump the amp rating to 24 & the wiring will be 12 gauge. Slow but steady & making progress. It's a pleasure to do this work without a time clock! I also need to grind out the right corner in the last pic. The wiring loom needs a place to bend onto it's final approach at the terminal block on the chassis (behind the paper towel). It's designed to just pull the front cover away & flip it upside down to rest on top for disconnection & servicing. Cool thing is when you design this much fortitude into a product & also plan ahead for servicing: The need for servicing goes away!!!!!!!!!!!

Start cap I went with was too long for the housing. Modified that & now it's a tight fit poking out of the housing. I should've taken a picture of that. Then, I had the motor mounted & removed 3 times in a single day & still could not get this lathe to power up on it's own. So, I took the motor to the motor shop & turned my attention to other projects. A month later I went & got my motor back. It was never touched or worked on. The centripical start contact has since been filed & polished. So, it's mounted & as long as I help the spin up when starting & only use the E Stop for quitting: All is well & more chips are happening as of today! This has been so important to me in part because I'm using this lathe to build parts for other machines that I'm restoring.