So I tried locking the ways and I think the gibs need adjustment when I pull the locking lever as far as they will go it still doesn't lock on any of the axes I also noticed that my table has a bit of play side to side in the Y axis is this normal?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Got My First Machine!

- Thread starter Izzy

- Start date

- Joined

- Feb 2, 2013

- Messages

- 3,627

Hi Izzy,So I tried locking the ways and I think the gibs need adjustment when I pull the locking lever as far as they will go it still doesn't lock on any of the axes I also noticed that my table has a bit of play side to side in the Y axis is this normal?

side to side clearance would indicate that the gibs will need adjustment.

is it normal? yes, for a maladjusted machine

but you can correct that.

but you can correct that.below is a manual pdf that may help you out

Attachments

- Joined

- May 4, 2015

- Messages

- 3,583

Wow , I just read all the posts ,jeeze sounds like an ulcer working. Hope you get the transformer , I'd Ck HGR also, they have tons of items like you need. There the problem is shipping cost plus there PACKING costs or skidding for forklift. You I think should take the motor and at least get it checked out , the bearings YA may want to replace while it's off. It's a beautiful machine and a little work by you and it should work longer then your lifetime. Good luck with your great mill.

@Ulma Doctor thanks! I'll post up with more updates as soon as I can things have been slow on the machine since ive been busy preparing for winter and what not.

@Silverbullet thank you! Its in alot better shape than I had first thought! I was told that most of the bearings where recently replaced so I want to get it running before I change any parts hell maybe I'll get lucky and it'll run mint! I plan on opening up the motor to see if the other 6 wires I need are inside or not if not im just going to bring it to a motor shop here in town but first things first I need run 220vac to the garage before anything else!

@Silverbullet thank you! Its in alot better shape than I had first thought! I was told that most of the bearings where recently replaced so I want to get it running before I change any parts hell maybe I'll get lucky and it'll run mint! I plan on opening up the motor to see if the other 6 wires I need are inside or not if not im just going to bring it to a motor shop here in town but first things first I need run 220vac to the garage before anything else!

Izzy,

I just discovered this thread and I couldn't believe the timing. I also recently purchased my first mill - a pair of Bridgeport Series II standard knee mills. I don't have the issue of choosing between static / rpc as I have 3 phase power available. I have one of the two machines up and running. On the other one, I have the voltage conversion issue to solve. The previous owner rewired the main power transformer and spindle motor for 240 volts. However, he never got it to run properly (said the motor would run but not reverse).

I have managed to acquire some schematics that seem to fit in general but I am still trying to understand them. The two machines are not the same - one has the controls in the same position as yours but the other one (the one that needs conversion) has the controls under the table to the right of the knee.

I'd be interested in getting a copy of the diagrams you emailed to Ted earlier.

Too bad we are so far apart - would be good to see your machine. I'm looking forward to hearing what you decide to do with your machine.

This machine is the one I have up and running.

This is the second machine with the controls under the table.

This machine also has more clearance between the table and the quill. The whole machine is about 7 inches taller than the other one.

I just discovered this thread and I couldn't believe the timing. I also recently purchased my first mill - a pair of Bridgeport Series II standard knee mills. I don't have the issue of choosing between static / rpc as I have 3 phase power available. I have one of the two machines up and running. On the other one, I have the voltage conversion issue to solve. The previous owner rewired the main power transformer and spindle motor for 240 volts. However, he never got it to run properly (said the motor would run but not reverse).

I have managed to acquire some schematics that seem to fit in general but I am still trying to understand them. The two machines are not the same - one has the controls in the same position as yours but the other one (the one that needs conversion) has the controls under the table to the right of the knee.

I'd be interested in getting a copy of the diagrams you emailed to Ted earlier.

Too bad we are so far apart - would be good to see your machine. I'm looking forward to hearing what you decide to do with your machine.

This machine is the one I have up and running.

This is the second machine with the controls under the table.

This machine also has more clearance between the table and the quill. The whole machine is about 7 inches taller than the other one.

Izzy,

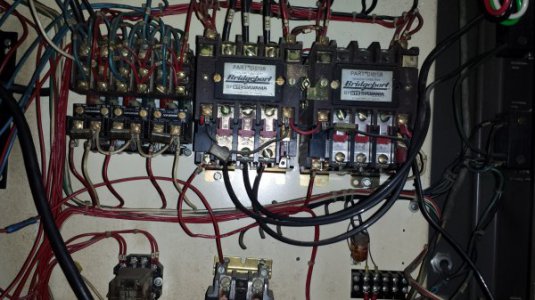

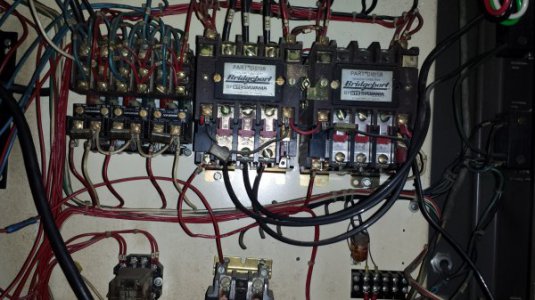

I just started looking at the machine that needs conversion this week. I'm sure the previous owner did not change fuses nor the heaters so I have to figure that out. I haven't yet figured out where the heaters are. My schematic gives some heater part numbers for different voltages but I haven't found any similar parts. Can anyone point them out to me on the images I uploaded?

I think there may be a wiring change necessary for the load meter but not sure.

I think only the 3 fuses where power enters the cabinet need to be changed. These fuses on this machine are BUSS NOS 45 (45 amp) while on the other machine are Bullet ECSR20 (20 amp) which doesn't make sense. Note the cabinets in these two machines are not the same. Even the size of the fuses is different.

Here are the contactors and the DBD Relay

Joe

I just started looking at the machine that needs conversion this week. I'm sure the previous owner did not change fuses nor the heaters so I have to figure that out. I haven't yet figured out where the heaters are. My schematic gives some heater part numbers for different voltages but I haven't found any similar parts. Can anyone point them out to me on the images I uploaded?

I think there may be a wiring change necessary for the load meter but not sure.

I think only the 3 fuses where power enters the cabinet need to be changed. These fuses on this machine are BUSS NOS 45 (45 amp) while on the other machine are Bullet ECSR20 (20 amp) which doesn't make sense. Note the cabinets in these two machines are not the same. Even the size of the fuses is different.

Here are the contactors and the DBD Relay

Joe

Last edited:

I feel like my machine may have been re-wired at some point as you still have all the Bridgeport parts in there all my parts are Allen Bradley. The heaters I'm pretty sure are on the left of the last photo just look very closely and they should have a W and a number on them like w46 for example. As far as powering my machine goes I've decided to just go with an rpc/transformer set up if the spindle motor doesn't have the connections for 220vac. looks like that first one might be a newer series 2 what are the serial numbers on them? Mine is 873 lol

I think the items on the left of the last photo are the relays for the table, knee up and knee down. The wire numbers match those in the schematics. That is referred to as the DBD relay. The schematic appears to say it is part of the left contactor assy which is the left contactor - center of the last photo. I've looked pretty closely and do not see any numbering like that or like the schematic indicates. For the 460 volt config, it would be H-2009-3 with a setting A, BMI 3154-2142. I don't see anything similarly numbered.

Joe

Joe