- Joined

- Aug 3, 2017

- Messages

- 2,437

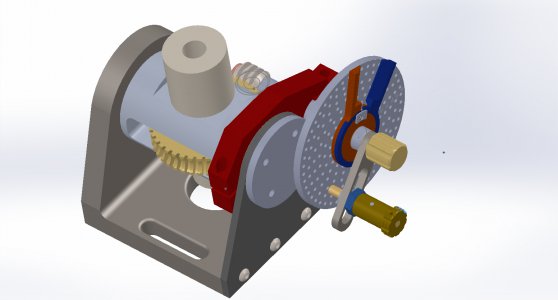

Isn't an indexing plate just a plate with a bunch of holes in it that a pin goes through? I don't really see a reason that couldn't just be a blank backing plate with a bunch of extra holes in itThe indexing plate as Mark did it would not hold the weight of a chuck. It was just for indexing, he had the nose of the spindle threaded to match his lathe chuck.

BUT it might be possible for me to design the indexing plate to be strong enough to mount a chuck to.

If we're doing something like that, I can volunteer for it. Largeish rounds are cheap enough to buy, and my lathe takes material quickly, so getting them to shape isn't a problem.

The indexing holes are of course a pain, but the DRO + a stubby length drill (Removes the need for a center drill) could likely get me done with not much time investment.