- Joined

- Apr 29, 2019

- Messages

- 2,244

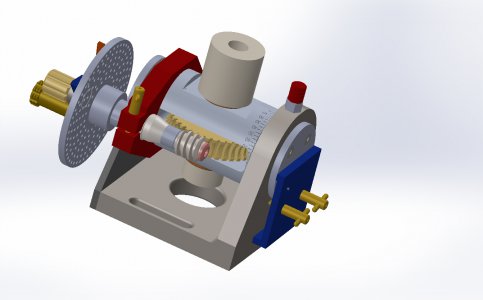

Another update.

I added the trunion locking and indexing features.

There are still a couple of areas that are just not right and I am still figuring out the best way to handle it

Welllllllll

It seems the step file has gotten to big for me to upload to this site. It is up to 15meg

I added the trunion locking and indexing features.

There are still a couple of areas that are just not right and I am still figuring out the best way to handle it

Welllllllll

It seems the step file has gotten to big for me to upload to this site. It is up to 15meg

Attachments

Last edited: