I dont think we were setting up to ship out one part each for checking. Last i knew we were just making them all and going to assemble. But either way one of each part of my will prob not be ready by then bc i am in the middle of doing my garage to get the mill and lathe going. I cant do some stuff without the mill also due to not having a drill press and i did say that earlier.

I think the overall project will go faster if you get set-up right first, and I still think I'm going to be the long pole.

My issue is just turning a huge amount of "not dividing head" into chips.* My technique and setup has been slowly improving, but even still I'm just now finishing up the bottom of the third Main Base. I did get the material rough cut for the Trunnion Crank, but it is going to have to sit and wait for its turn on the mill.

I've spent a lot of time in reseting and rearranging to get the entire part within the range of movement of my mill, and then getting it rigid enough to hit the numbers. Nothing is more frustrating than getting set-up, wonder why the cut isn't progressing or is crooked, and then realizing that the part is moving in the vice.

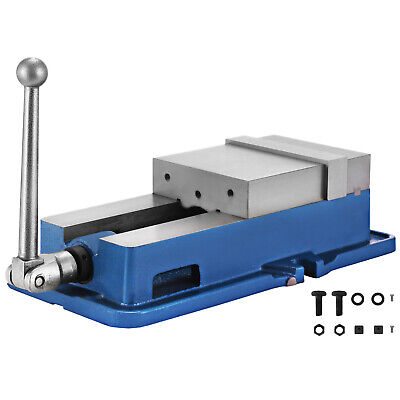

Which is how I broke my Chinesium vice last week. I kept cranking down trying to stop the piece from walking all over the place. Fortunately, I got two new ones in Saturday morning. . . a 6" precision vice, and a 4" screwless. Turns out that a 6" vice looks silly sitting on a RF-30 clone, taking up nearly the entire table, but the rigidity is awesome. Combined with the almost silent 3Hp DC motor, the cuts I did yesterday not only came out straight, but the cutting wouldn't have woken a sleeping baby. No vibration or chatter to speak of.

The bucket that I'm keeping scraps and chips in probably weighs 30lbs at this point.

*A famous sculptor (Michael Angelo?) was asked how he did it. His response was he starts with a image, and cuts away what doesn't belong.

Tonight i may forgo the painting and maybe start a part or 2. I dont want to keep holding everyone up more due to my garage project

Tonight i may forgo the painting and maybe start a part or 2. I dont want to keep holding everyone up more due to my garage project