-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Group Project: Dividing Head - The Build

- Thread starter Flyinfool

- Start date

- Joined

- Mar 25, 2013

- Messages

- 4,622

I figured that. My gear is only 3.4" dia. so it is not necessary. I can add it if someone makes the 3.6" gear.The chamfer on the small end is to clear the OD of the driven gear when engaged.

BTW I think there will be a clearance problem with a 3.6" gear. As the gear teeth wrap further around the worm, it takes a greater distance to disengage related to the sin of the angle at the edge of the gear. Think about an exaggerated situation where the gear encloses 50% of the worm diameter. It doesn't matter that the tooth depth is only .125. It would take a lot more distance to clear the teeth at the edges.

So far I feel like the 3.4" gear will be very effective if I can get the teeth cut a little deeper. Stay tuned!

To above that asked the spindle I hope will

Be rebuilt in a few weeks. Not sure on that shouldn’t be more than a month total

I wish some of y’all were local to me… I have a 3axis cnc that sits unused most days. I have a huge backlog of projects since so much stuff went wrong building the new shop.

If anyone is ever on the east side of Atlanta and wants to come visit let me know.

Are there any drawing changes to the trunion or dividing plates? Those are the parts I have material for and I signed up for.

My goal with the trunion is to do all operations from one setup to reduce the chance of runnout etc. then I can just flip it in some bored soft jaws and do the other side facing etc.

If it is needed I also have a cylindrical grinder.

Surface grinder is still a work in progress…. Same with the shaper. And the south end lathe…

Read a little more up above. I do have a tig welder if you want to go with that but also I can look at the price to order some 3.5” stock if we need a larger diameter. I believe I have 3.25” on hand.

Be rebuilt in a few weeks. Not sure on that shouldn’t be more than a month total

I wish some of y’all were local to me… I have a 3axis cnc that sits unused most days. I have a huge backlog of projects since so much stuff went wrong building the new shop.

If anyone is ever on the east side of Atlanta and wants to come visit let me know.

Are there any drawing changes to the trunion or dividing plates? Those are the parts I have material for and I signed up for.

My goal with the trunion is to do all operations from one setup to reduce the chance of runnout etc. then I can just flip it in some bored soft jaws and do the other side facing etc.

If it is needed I also have a cylindrical grinder.

Surface grinder is still a work in progress…. Same with the shaper. And the south end lathe…

Read a little more up above. I do have a tig welder if you want to go with that but also I can look at the price to order some 3.5” stock if we need a larger diameter. I believe I have 3.25” on hand.

Last edited:

- Joined

- Aug 13, 2020

- Messages

- 1,342

Give it a quick dip in Evaporust first?

Honestly, I think 1/8" of a ledge is plenty. I've used an air chamfering tool on all the edges, so they are very consistent. If you provide the corner relief going laterally into the trunnion, it should have all but .010" of that 1/8" all the way around. That is, plunge the lathe tool into the trunnion at the inside corner of the clamping ledge. Almost like you were going to install a clip ring.

Honestly, I think 1/8" of a ledge is plenty. I've used an air chamfering tool on all the edges, so they are very consistent. If you provide the corner relief going laterally into the trunnion, it should have all but .010" of that 1/8" all the way around. That is, plunge the lathe tool into the trunnion at the inside corner of the clamping ledge. Almost like you were going to install a clip ring.

- Joined

- Mar 25, 2013

- Messages

- 4,622

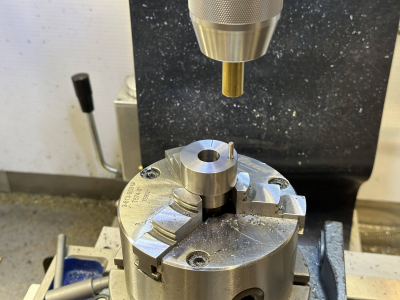

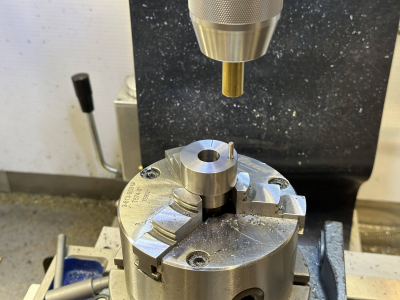

I finished the mill work without a hitch!

The scribed line on the face indicated TDC of the eccentric.

I tried something new this time. Since alignment for these small pins is so critical to pressing, I used a brass bar in the mill to press them in. I know it is not best practice but it worked great!

The scribed line on the face indicated TDC of the eccentric.

I tried something new this time. Since alignment for these small pins is so critical to pressing, I used a brass bar in the mill to press them in. I know it is not best practice but it worked great!

Last edited:

Give it a quick dip in Evaporust first?

Honestly, I think 1/8" of a ledge is plenty. I've used an air chamfering tool on all the edges, so they are very consistent. If you provide the corner relief going laterally into the trunnion, it should have all but .010" of that 1/8" all the way around. That is, plunge the lathe tool into the trunnion at the inside corner of the clamping ledge. Almost like you were going to install a clip ring.

Being hot rolled the od of the bar is not perfectly round and has pitting and mill scale