- Joined

- Oct 31, 2016

- Messages

- 2,644

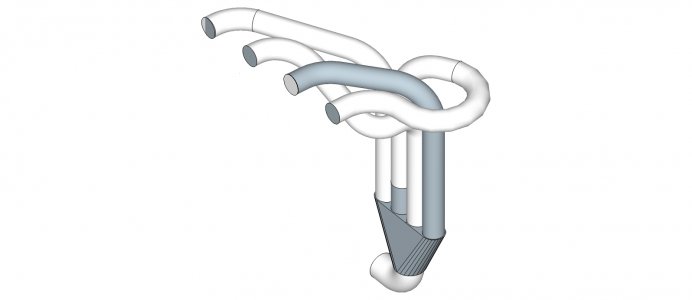

I did the math for ideal primaries and collectors. 1 3/8 tubing is the ideal size for the primaries on this engine in a stock configuration. The length should be 33.5". No way to get the ideal length. The collector is slightly bigger than ideal and the ideal size out the back is 1 7/8 OD. It is better to be slightly under size for a street engine than to be over size. That is why I am going with a 1 3/4 OD back to the muffler.

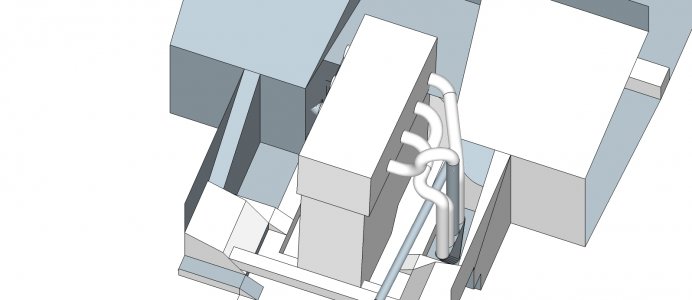

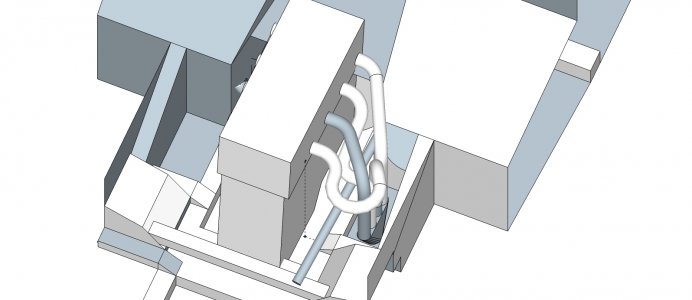

On the number 4 cylinder a 2.5" radius won't fit. There is only 3.5" from the head to the foot well. On all of the other cylinders if you use 2.5 radius bends the header will run into a frame rail and the inner fender well. There is only 6.5" from the head to the center of the slot. The only place that I could use a 2.5" radius bend would be on the last bend going down to the collector. This is just a street car. The main consideration is to get the exhaust somehow to the back of the car.

If I could use 2.5 radius bends I would. And I would have a better header. I did a design with 2.5 radius bends only to discover that it would not fit in the car. Doesn't do much good if it won't fit in the car.

On the number 4 cylinder a 2.5" radius won't fit. There is only 3.5" from the head to the foot well. On all of the other cylinders if you use 2.5 radius bends the header will run into a frame rail and the inner fender well. There is only 6.5" from the head to the center of the slot. The only place that I could use a 2.5" radius bend would be on the last bend going down to the collector. This is just a street car. The main consideration is to get the exhaust somehow to the back of the car.

If I could use 2.5 radius bends I would. And I would have a better header. I did a design with 2.5 radius bends only to discover that it would not fit in the car. Doesn't do much good if it won't fit in the car.