-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heavy 10 project

- Thread starter woodtickgreg

- Start date

- Joined

- Jun 22, 2012

- Messages

- 1,552

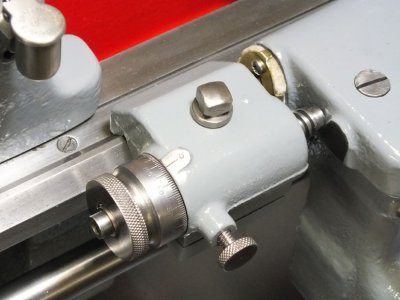

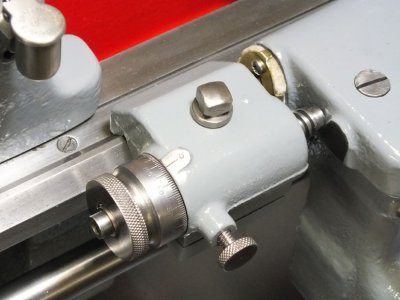

Well since I was picked for pom I better show you guys that I am working on the lathe when I can, a couple hours a day after work. I still do things one component or group of parts at a time due to lack of space, I work on a small tool cart. In the pics you can see some finished parts. I got the back gear with the new used handle installed, my handle was broken off when I got the lathe. One tooth on the back gear was a little mushed so I spent some time with a needle file and reshaped it, it works perfectly now. I cleaned up the micrometer stop and installed that too, It was very rusty when I got the lathe.

Well since I was picked for pom I better show you guys that I am working on the lathe when I can, a couple hours a day after work. I still do things one component or group of parts at a time due to lack of space, I work on a small tool cart. In the pics you can see some finished parts. I got the back gear with the new used handle installed, my handle was broken off when I got the lathe. One tooth on the back gear was a little mushed so I spent some time with a needle file and reshaped it, it works perfectly now. I cleaned up the micrometer stop and installed that too, It was very rusty when I got the lathe.

Last edited:

- Joined

- Jun 22, 2012

- Messages

- 1,552

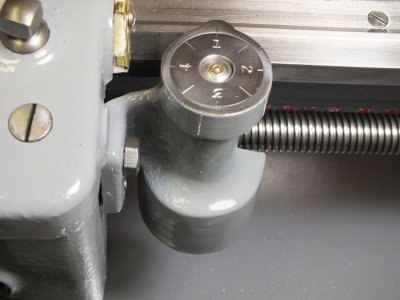

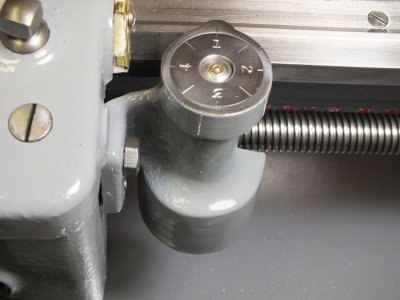

I also reworked the thread dial and installed it. And a pick of all the working parts all clustered together. I am currently working on all the gears that mount on the side of the head stock. I am finally feeling like I am in the home stretch. after the gears I have all the covers to do, the tail stock, the switch, the worklight, and then run a power line and purchase and hook up a vfd.

I also reworked the thread dial and installed it. And a pick of all the working parts all clustered together. I am currently working on all the gears that mount on the side of the head stock. I am finally feeling like I am in the home stretch. after the gears I have all the covers to do, the tail stock, the switch, the worklight, and then run a power line and purchase and hook up a vfd.

Last edited:

- Joined

- Oct 6, 2012

- Messages

- 486

Exceptional work if I may say so!

- Joined

- Oct 30, 2012

- Messages

- 19

That is a great looking lathe. I can't believe how clean it is. It is very similiar to the one I bought last month concerning the controls and such. Mine is a 1933, 11" swing, 4' bed as best I can figure. I had the three and four jaw chuck with mine, but was missing the collet bushing and spindle nut. I have a set of collets, but haven't figured out what size they are yet. It appears they are 3/4-20 thread and .750 in diameter. The chart I looked up was neither 5C or 3C.

- Joined

- Jun 22, 2012

- Messages

- 1,552

I don't know if anyone has noticed but the thread dial does not line up with the machined pad on the saddle. This is obviously not the correct thread dial for a heavy 10L lathe. I wonder what it is for? So at this point I am looking for a thread dial for a heavy 10L. Maybe if I can find out what it does fit I can sell the one I have and put it toward the purchase of a correct one, or maybe a trade?

- Joined

- Jun 21, 2012

- Messages

- 193

Get yerself a tee-shirt! You could have the headstock on the back, ways on either sleeve, etc. etc.:winner: