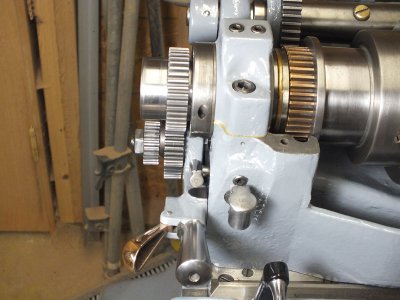

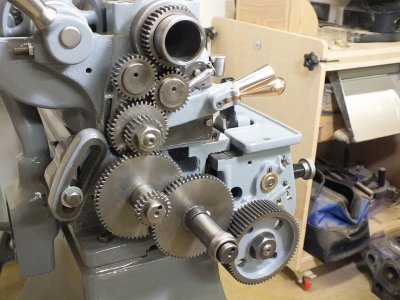

Here's a couple of pics of all the gears installed, everything turns freely by hand. The little bronze reverser lever really polished up well, I hand sanded some nicks and dings out of it and then buffed it. I think it is my favorite piece on the lathe! I took care to make sure all the gears had full engagement and where centered as best as possible. Next I gathered up all the covers as seen in the pic. I was missing the bull gear flip cover and I found a set of bull gear/back gear covers with the flipper on ebay. The new/used covers are cast iron, mine where aluminum. I then washed them in the parts washer to degrease them. I am going to take this to a media stripper by me to have them glass beaded to remove the paint and make ready for repainting. The reason I degreased them is so they didn't get grease in the strippers blast cabinet, little things like this are appreciated by vendors and you usually get better service in the long run.

View attachment 42537View attachment 42538View attachment 42539. Woodtickgreg, everyones work I look at, is beyond words that I know of, to tell them how great their work is. One member, who has been helping me is Rick. He ask me to send pictures of my problem, but i can't seem to get a picture from cell phone to I Pad. Then I saw your pictures, what I have now is in pictures number 53 kb and 60 kb. What i don't have and need to know is, as pictures in 100 kb and 101 kb, what is the diameter of the gears located at the end of lead screw, I think it is 56T, and the small one on top, may be a 20T. I have some gears,but may be for a regular 9. If you could help me out, I would so thankful, Chester