Frame sizes for motors are now standardized under a system established by NEMA:

www.engineeringtoolbox.com/nema-electrical-motor-frame-dimensions-d_1504.htm

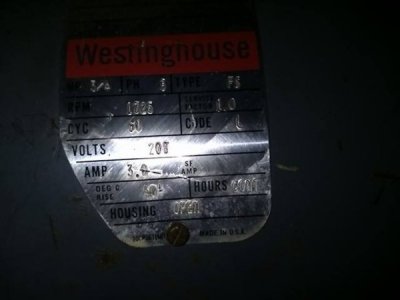

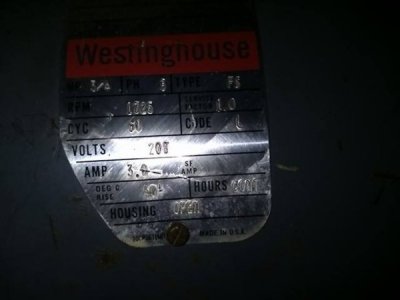

On older machines, motors were built to different frame and mounting dimensions which may not correspond to the current standards. My Logan was like that: the motor

plate indicated it was a "118" frame motor, which has no exact equivalent in the NEMA standard. I was able to compare dimensions and found that a NEMA 56 frame

motor would fit the mount, which was handy since the 56 frame is extremely common and easy to find. If you have a look at the standard and measure your motor

mount you should find a NEMA frame that will fit, or if you post a question on the South Bend sub-forum, someone might be able to give you the answer. Charles is right,

changing motors might be easiest. I found my motor as new old stock on eBay for about 1/2 of the usual retail price, or, if you use a common frame size, you might be able to find a used

motor. Do you have single phase 220V

available at the lathe, or 110V?