Good Afternoon,

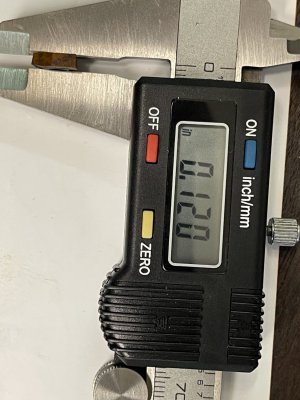

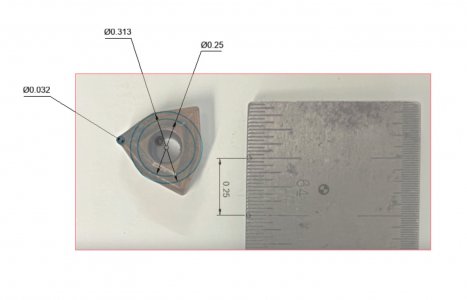

When I purchased my K.O. Lee T&C Grinder several months ago, the seller sent along a bunch of other items. This included several indexable drills that had hard lives but still useable. I'm trying to figure out what type and size inserts they use and I'm hoping the photo below might enable someone to identify the insert and provide some much needed guidance.

Thanks in advance.

Joe

When I purchased my K.O. Lee T&C Grinder several months ago, the seller sent along a bunch of other items. This included several indexable drills that had hard lives but still useable. I'm trying to figure out what type and size inserts they use and I'm hoping the photo below might enable someone to identify the insert and provide some much needed guidance.

Thanks in advance.

Joe