-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help with using an abrasive saw on material

- Thread starter Brento

- Start date

Abrasive saws are good for 1\4 inch and thinner structural type of steel and tubing. I have not had very good luck with them on solid bar stock over about 3\4 of an inch. Tried it on an inch and half and could have cut it faster with a hack saw.

@Nutfarmer if i wasnt cutting some stainless id use a hacksaw. The stainless ate my teeth like nothing.

Wrong saw to try and use on aluminum. If you use the abrasive blade on aluminum you risk blowing up the blade and injury . The saw rmp is too high for a carbide saw blade. Use a hand hack saw until you can find a horizontal band saw

@Nutfarmer i wasnt going to use the abrasive on aluminum. I though of using a different blade until i found out the rpm situation.

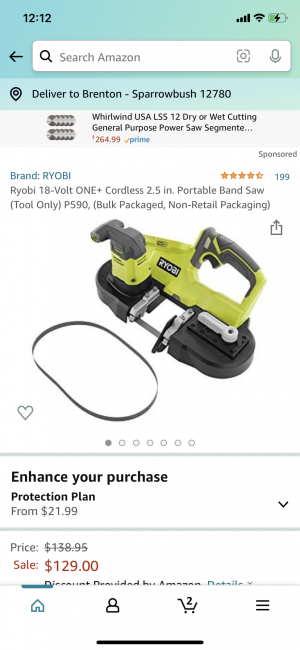

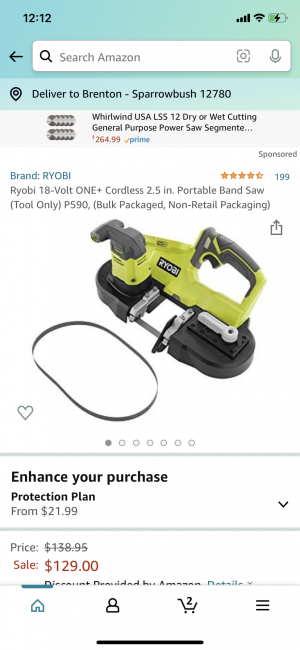

Quick stupid question. Would i be better off getting one of these?

Quick stupid question. Would i be better off getting one of these?

The problem with that weak abrasive saw is that the blade is not cutting hard enough and it gets glazed. Then, it doesn't cut. It just wastes power and glazes more. If you want to cut larger bar stock, either use a band saw or a real abrasive saw. The real abrasive saws are not under-powered. They have a 3 phase induction motor and multiple belts

A good bi metal hack saw blade can make a world of difference. I can appreciate the frustration on not always having what we need to make the job easier. Slowly and surely we accumulate more tooling as we can. Good luck on your project

@Nutfarmer what brand a tpi do you recommend on stainless and regular steel?