B

Bill Gruby

Forum Guest

Register Today

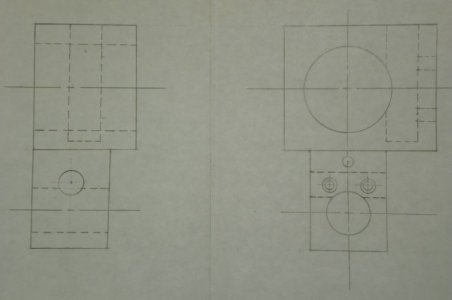

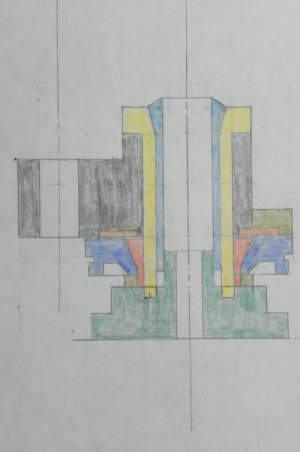

Today will be spent designing the new Tool Holder to accept the 5C Collets. I will be using most of the Bonelle design for this as no casting is required. Martin Models has a enlarged casting for this also. I chose the 5C Collet for its size and also that square holders are available.

"Billy G"

"Billy G"

Last edited by a moderator: