- Joined

- Sep 10, 2022

- Messages

- 928

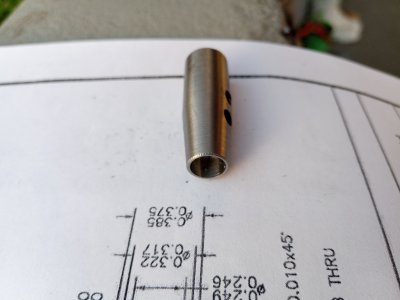

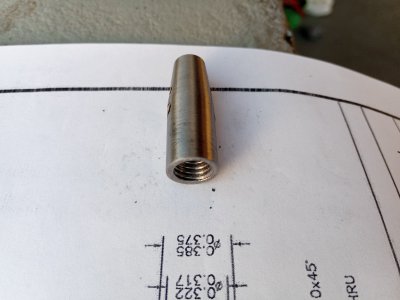

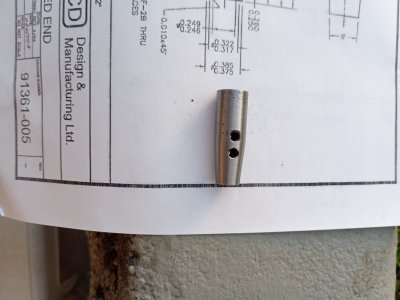

15 minutes each on manual machines is well within reason. Figure 1 hour for set up of both machines.

5 hrs labor

1 hr setup

Material cost.

If you do not have in stock

10mm taps plug and bottom

10-32 tap

.248 reamer

How fast do they need it? The faster the better premium you can charge.

No back log of jobs. I would go.

3-5 day delivery. For regular time.

Expedited I would go 2 days 30% up charge. If doing this you better have Everything in stock.

Cutting oil is my blood.

5 hrs labor

1 hr setup

Material cost.

If you do not have in stock

10mm taps plug and bottom

10-32 tap

.248 reamer

How fast do they need it? The faster the better premium you can charge.

No back log of jobs. I would go.

3-5 day delivery. For regular time.

Expedited I would go 2 days 30% up charge. If doing this you better have Everything in stock.

Cutting oil is my blood.