- Joined

- Mar 27, 2022

- Messages

- 421

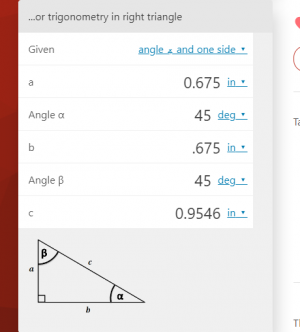

I’m playing around making a bench block and want to add a Vee in the center. I have it mounted at 45* and a 5/8” end mill. I have indicated center line on it but after thinking I think my slot would be off center if I stayed there.

My current thought is that I made a line 5/16” lower measured on the face of the part and aligned the edge of the end mill with that. If it works how I think it “should” be in the center when the end mill reaches full depth on the end face of it? I think I would only be turning X axis for depth and Y for the slot. I would leave Z alone? Seems logical in my head but I’m not sure if I have the thought right, the 45* angle is really skewing my thoughts. Maybe I need to make a 45* box for me to stand on so I can see the big picture. Here’s some pictures of the setup.

My current thought is that I made a line 5/16” lower measured on the face of the part and aligned the edge of the end mill with that. If it works how I think it “should” be in the center when the end mill reaches full depth on the end face of it? I think I would only be turning X axis for depth and Y for the slot. I would leave Z alone? Seems logical in my head but I’m not sure if I have the thought right, the 45* angle is really skewing my thoughts. Maybe I need to make a 45* box for me to stand on so I can see the big picture. Here’s some pictures of the setup.