- Joined

- Nov 5, 2018

- Messages

- 100

I have gotten a lot done on a lathe that I'm cleaning up to use and I started a thread about it here: https://www.hobby-machinist.com/threads/new-to-me-compact-8-cleanup-thread.74067/

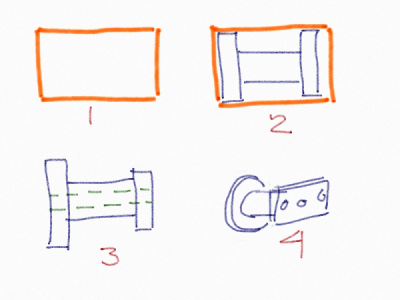

I didn't notice that the cross slide lead screw mount was broken until I was taking it apart. This one looks like someone either used solder of possibly jb weld to try and keep it pieced together and painted over it, but when I took it off, it just fell apart into 3 pieces. It seemed to work great but it can't be good to leave it pieced together like it was. I'm good at taking things apart and putting them back together, but I'm no machinist (yet ). Can anyone tell me how I could make a part like this and have it work out well? I'd love to do one in aluminum if possible. I priced used cross slides on eBay but they are really pricey and they would still have the zamak screw mount that could possibly cause problems later.

). Can anyone tell me how I could make a part like this and have it work out well? I'd love to do one in aluminum if possible. I priced used cross slides on eBay but they are really pricey and they would still have the zamak screw mount that could possibly cause problems later.

Could anyone give me some pointers on a way to tackle making something like that. I only have an older 7x10 HF lathe and drill press so I'm limited on tools to help with the job. I do have a lot of wood working tools (table saw, bandsaw, routers ect) but I'm afraid they won't be real helpful for this.

Anyone have an advise on what I could make given the tools I currently own? Thanks for advice anyone may have!

I didn't notice that the cross slide lead screw mount was broken until I was taking it apart. This one looks like someone either used solder of possibly jb weld to try and keep it pieced together and painted over it, but when I took it off, it just fell apart into 3 pieces. It seemed to work great but it can't be good to leave it pieced together like it was. I'm good at taking things apart and putting them back together, but I'm no machinist (yet

Could anyone give me some pointers on a way to tackle making something like that. I only have an older 7x10 HF lathe and drill press so I'm limited on tools to help with the job. I do have a lot of wood working tools (table saw, bandsaw, routers ect) but I'm afraid they won't be real helpful for this.

Anyone have an advise on what I could make given the tools I currently own? Thanks for advice anyone may have!