-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I ordered a PM-940M-PDF

- Thread starter Dan_S

- Start date

- Joined

- Aug 26, 2013

- Messages

- 1,061

Hey coolidge,

I made them out of 8620, because it turns decently, and welds well.

To clean the tube I used one of these.

http://www.homedepot.com/p/Avanti-P...oven-Quick-Strip-Disc-PNW045STRB01G/202830907

It cuts fast but doesn't last that long, I burned through about 80% of one cleaning up the tube. Next time I need to clean a bunch of tubing, I think I'll try the Norton rapid strips and see if they last any longer.

I made them out of 8620, because it turns decently, and welds well.

To clean the tube I used one of these.

http://www.homedepot.com/p/Avanti-P...oven-Quick-Strip-Disc-PNW045STRB01G/202830907

It cuts fast but doesn't last that long, I burned through about 80% of one cleaning up the tube. Next time I need to clean a bunch of tubing, I think I'll try the Norton rapid strips and see if they last any longer.

- Joined

- Mar 12, 2014

- Messages

- 1,531

Looking good. I think you will be happy getting it up off the ground a bit and at a more comfortable height. My last lathe/mill I put up with for 16+ years of being too low thinking some day I would raise it up. When I bought new machines last year the first thing I did was get them at a comfortable height even before getting them operational. I knew if I didn't do it immediately I probably wouldn't do it at all and that was not going to happen again.

Mike.

Mike.

- Joined

- Aug 26, 2013

- Messages

- 1,061

So it's been 17 days since the mill showed up, and it's now 100% set up and ready to go. I got it up on the stand tonight and level it.

As it stands the table top is 41.5" off the floor, and that puts both the x & y axis wheels at the perfect height for me.

to mount the base/riser to the stock stand, I used 6" long 1/2"-13 grade 8 bolts.

It took 2 and a half hours to level the mill, but it seemed like forever. Getting down on your knees to make an adjustment, and then standing back up to check the level was a killer.

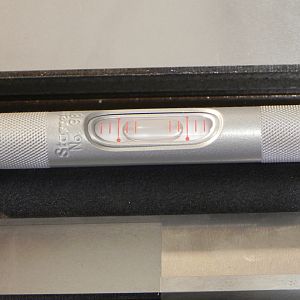

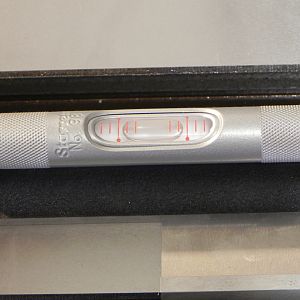

x-axis

y-axis

As it stands the table top is 41.5" off the floor, and that puts both the x & y axis wheels at the perfect height for me.

to mount the base/riser to the stock stand, I used 6" long 1/2"-13 grade 8 bolts.

It took 2 and a half hours to level the mill, but it seemed like forever. Getting down on your knees to make an adjustment, and then standing back up to check the level was a killer.

x-axis

y-axis

- Joined

- Mar 12, 2014

- Messages

- 1,531

Turned out awesome. You will be glad you put in on a riser base.

Mike.

Mike.

- Joined

- Oct 27, 2014

- Messages

- 10

Hey Dan, I am considering the same mill and wondering the dimensions needed (floor space) to get full travel and to get behind like you did in your video. I have a small shop and trying to do some space planning to get ready for the mill. Thx

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

- Joined

- Mar 8, 2015

- Messages

- 53

Hey Bnixon,Hey Dan, I am considering the same mill and wondering the dimensions needed (floor space) to get full travel and to get behind like you did in your video. I have a small shop and trying to do some space planning to get ready for the mill. Thx

Sent from my iPhone using Tapatalk

I have my 940 set up at 54" deep and 77" wide, that is w/table travel set at 22" w/feed, and also leaves room at rear to open electrical panel. The height from the top of motor to floor is almost 86", thats motor at its upmost stop and mill pedestal setting on the floor.