-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ideas for easy and cheap chip guard for mill ?

- Thread starter Cr2348455

- Start date

- Joined

- Aug 13, 2020

- Messages

- 1,342

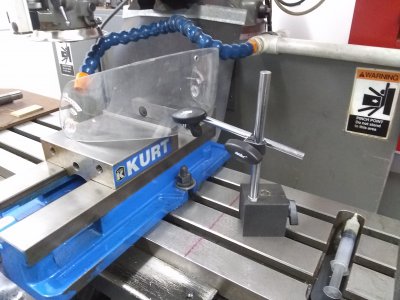

I just use my old face shields from my motorcycle helmets and attach them to a cheap mag base. They seem to be good for keeping about 75-80% of the chips from ending up on the floor.

Ted

Ha! I just remembered that I have a couple of those in a drawer that were too banged up to ride behind. I'm thinking about a flip up guard like what comes shipped with most grinders. Mount it on the front of the quill

Thanks Ted !I just use my old face shields from my motorcycle helmets and attach them to a cheap mag base. They seem to be good for keeping about 75-80% of the chips from ending up on the floor.

Ted

View attachment 363518View attachment 363519

- Joined

- Feb 17, 2013

- Messages

- 4,406

You can get heavy flexible grey vinyl "shower pan liner" at big box stores. IIRC, it's about 48" wide and they'll cut the length you want from a roll. Pretty inexpensive, and not too bad with hot chips.I think I'm just getting use to having chips everywhere. Not really.

It drives me nuts. I like the plastic with the magnets idea, as long as the magnets are up out of the way. magnets can be a real PITA

I was thinking about some rubber material to snug up against the side of the mill vise and lay out across the table and surrounding apparatus.

Like a truck inter tube maybe. Heavy enough to hold and easy to pick up and dump in the can.

- Joined

- May 3, 2017

- Messages

- 1,997

Here's a link to the one I made last year. I use it almost every time I'm on the mill.

Regards,

Terry

www.hobby-machinist.com

www.hobby-machinist.com

Regards,

Terry

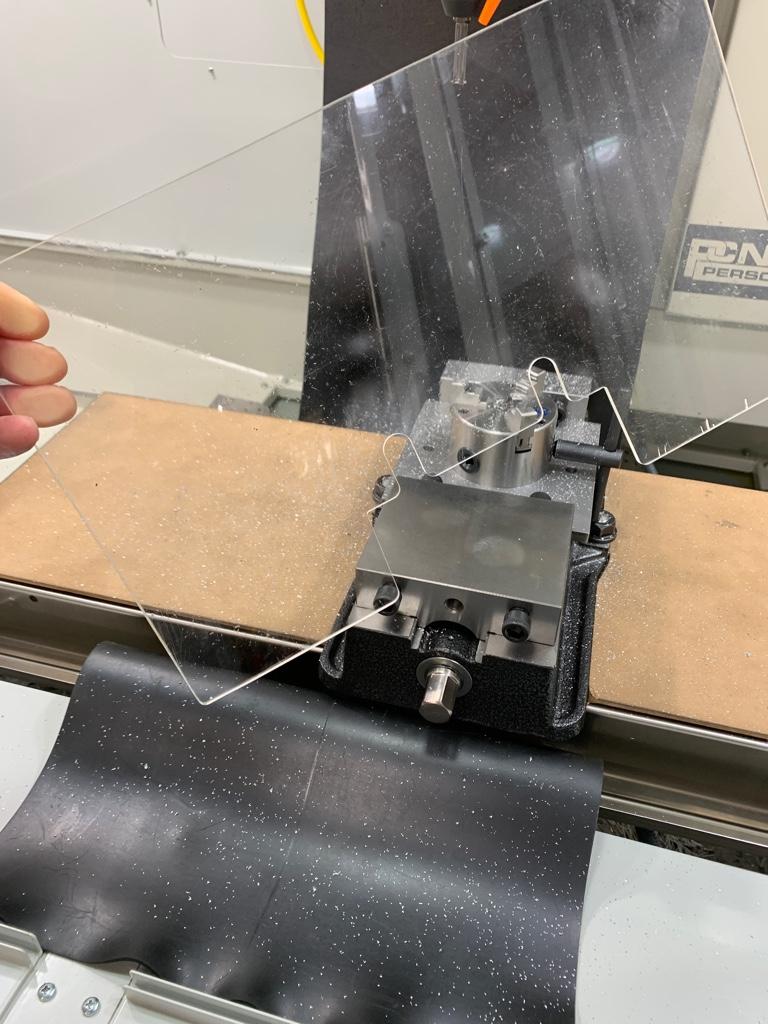

Another Chip Shield

I made this chip shield out of clear plexiglass and some scrap aluminum. I did a lot of head-scratching before beginning the build. I tried to anticipate every conceivable application with regard to size of milling projects and safety. Once I zeroed in on these criteria, I came up with a...

www.hobby-machinist.com

www.hobby-machinist.com

Excellent job, thanks for the link.Here's a link to the one I made last year. I use it almost every time I'm on the mill.

Regards,

Terry

Another Chip Shield

I made this chip shield out of clear plexiglass and some scrap aluminum. I did a lot of head-scratching before beginning the build. I tried to anticipate every conceivable application with regard to size of milling projects and safety. Once I zeroed in on these criteria, I came up with a...www.hobby-machinist.com

- Joined

- May 4, 2019

- Messages

- 792

I have a few cheap mag bases with pieces of plastic attached, Masonite would work just as well. I set them on the machine table to block chips. On the front of my Kurt clone vise there are two screw holes. I fit another piece of plastic about 18" wide to drop over cap screws in those holes. I try to machine in a direction that throws the chips forward, toward the guard on the vise. Some people with ram type machines have made brackets to fit under the ram to hold pivoted outriggers to support curtains, probably cut down welding curtains.

Thanks Illinoyance!I have a few cheap mag bases with pieces of plastic attached, Masonite would work just as well. I set them on the machine table to block chips. On the front of my Kurt clone vise there are two screw holes. I fit another piece of plastic about 18" wide to drop over cap screws in those holes. I try to machine in a direction that throws the chips forward, toward the guard on the vise. Some people with ram type machines have made brackets to fit under the ram to hold pivoted outriggers to support curtains, probably cut down welding curtains.

- Joined

- Oct 30, 2012

- Messages

- 960

I have a few cheap mag bases with pieces of plastic attached, Masonite would work just as well. I set them on the machine table to block chips. On the front of my Kurt clone vise there are two screw holes. I fit another piece of plastic about 18" wide to drop over cap screws in those holes. I try to machine in a direction that throws the chips forward, toward the guard on the vise. Some people with ram type machines have made brackets to fit under the ram to hold pivoted outriggers to support curtains, probably cut down welding curtains.

I’m with you... sounds like we have similar methods. One key feature that quickly becomes apparent with chip shields whether lathe or mill is simplicity. To use, clean, maintain, store and adapt to any situation. Sometimes absolute containment effectiveness must be sacrificed for ease of use. I’ve tried magnets but found cleaning off chips between parts was a pain so I default to gravity. An old v-block jaw that already had some tapped holes and pc of masonite became an easy set it wherever shield.

Sent from my iPhone using Tapatalk