Why am I doing this? A number of reasons. I have loved machines since before I could talk. My first word was "wheels." My working life was spent inventing on demand and designing machines, tooling, and assembly/manufacturing processes. My father was a machinist with his own shop and I grew up making things with my hands and doing work for my dad. I am using my father's micrometers, dial calipers, machinist scales, squares, and other measurement tools, most of which are older than the lathe, and that is pleasant because I think of him often.

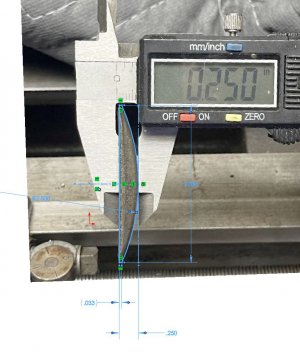

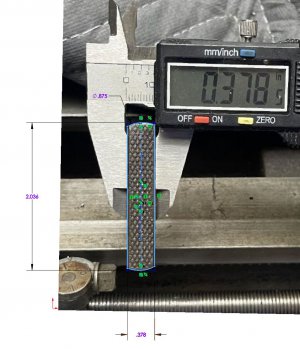

I was given this lathe and it was missing some parts so I started joining groups like this, trying to find out more about the lathe and what parts were needed and how to acquire them. I noticed that there was a fair number of people wanting to know dimensions for things like the pulleys.

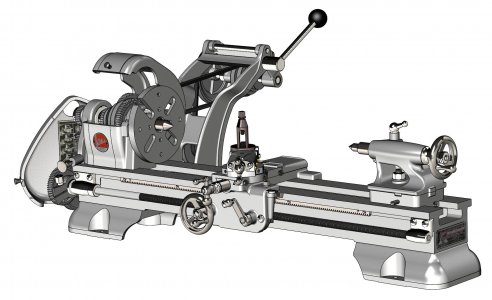

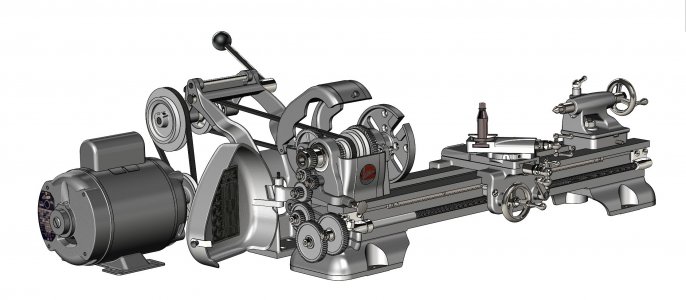

So I thought I would get a seat of Solidworks, model the lathe, create drawings of things that people might make for themselves, and learn something about the machine in the process. And have fun. Eventually I hope to get into 3D printing and create and test STL files so that people can make parts that might function if they were made out of plastic. I know folks have already done the change gears and put them on sites like Thingiverse. Maybe they have done the other parts, also. I plan to go that route anyway because I think it will be fun.

It has been a blast so far. Besides the modeling, there is also pleasure in documenting a machine that was first sold in the form that I have in 1939 and was produced unchanged for almost 40 years. How many products can we think of that have been on the market for that long with undergoing significant design changes? And many of the parts have features that were hand-ground and when I am measuring them it brings to mind that quite some time ago some person held this in their hands and shaped this part. So the modeling process feels like it's preserving a piece of history and honoring those who designed and manufactured it for all those years. I know, that's a bit out there, but it is another one of the reasons I enjoy doing this.