- Joined

- Sep 14, 2014

- Messages

- 438

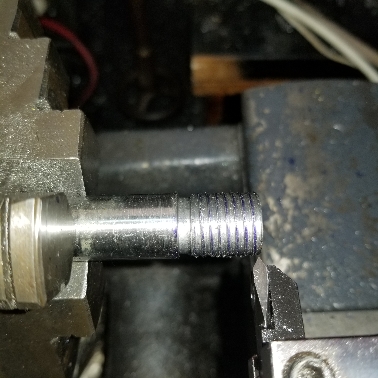

Arggg 2nd attempt to post.

1. Martin W. Was spot on. Slap forehead.

2. Mattthmuppet2, these are HHS, still expensive but are supposed to be easy to sharpen putting the flat on a stone/ diamond.

3. ARW has zero, 0, none, nada pictures on their site.

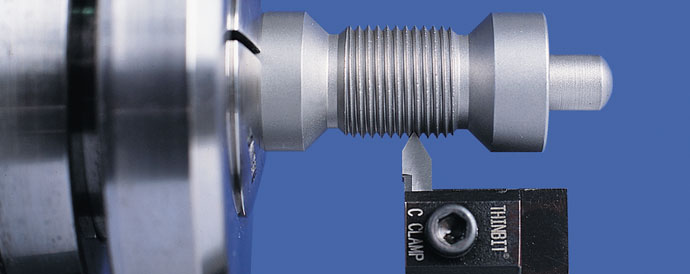

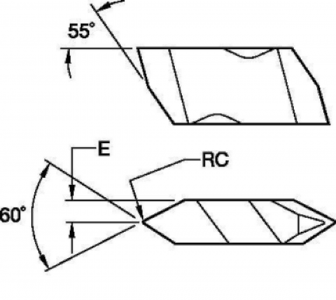

4. Only took 4 emails with the A R Warner tool company to figure out that the proper tool orentation is shown in an 8 year old video at marker 2:34 for :30 seconds while describing proper tool height. Got that only after I sent them a picture and was told to look at the video. They told me: "There is a wealth of information on our hobbyist page." Not a single picture of the tool in a tool holder, no links to any forum with postings of their tool in use, just to people saying what a great tool it is. Guess their hobbiest tool is only meant for hobbiest's who already know what they can't be bothered to show.

5. At least there is now one posting here on the tool. Hope it will help others.

Have very limited shop time as injury limits me to ~ :45 of standing. Will report when able on how using the tool in.the proper orentation works.

So again, thanks very much!

Ron

1. Martin W. Was spot on. Slap forehead.

2. Mattthmuppet2, these are HHS, still expensive but are supposed to be easy to sharpen putting the flat on a stone/ diamond.

3. ARW has zero, 0, none, nada pictures on their site.

4. Only took 4 emails with the A R Warner tool company to figure out that the proper tool orentation is shown in an 8 year old video at marker 2:34 for :30 seconds while describing proper tool height. Got that only after I sent them a picture and was told to look at the video. They told me: "There is a wealth of information on our hobbyist page." Not a single picture of the tool in a tool holder, no links to any forum with postings of their tool in use, just to people saying what a great tool it is. Guess their hobbiest tool is only meant for hobbiest's who already know what they can't be bothered to show.

5. At least there is now one posting here on the tool. Hope it will help others.

Have very limited shop time as injury limits me to ~ :45 of standing. Will report when able on how using the tool in.the proper orentation works.

So again, thanks very much!

Ron