- Joined

- Mar 26, 2018

- Messages

- 2,724

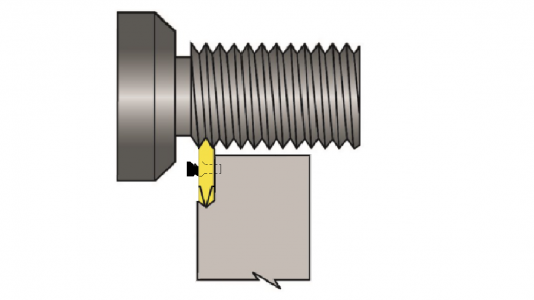

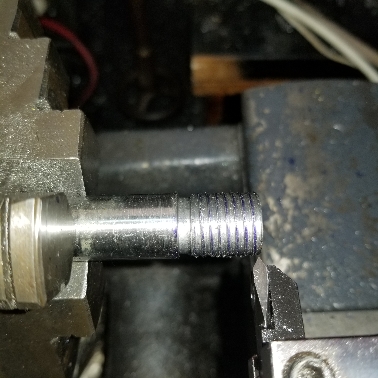

Snuck out to the shop for a quick trial. Yes the interesting thing about this cutter is that the screw goes into what is the side the cutter not the top. Could not find a single image illustrating this type of tool holder and cutter.

Look up the indexable cutter designation MTVOR. This is a moderately common threading holder - I have one too.

Looks like you now have it set up correctly in the tool post. Your pictures do not show compound angle, but I'll assume you know what you are doing there.