- Joined

- Nov 14, 2016

- Messages

- 3,001

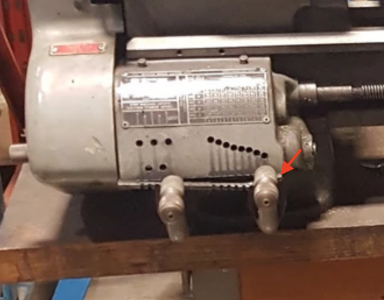

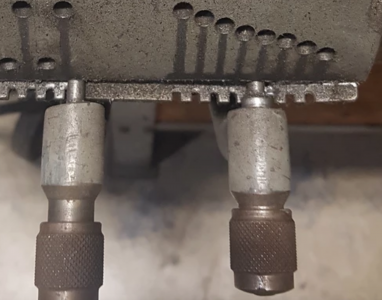

My lathe has a .75” bore. However the chuck is not quite .75 so the effective bore is less than that.

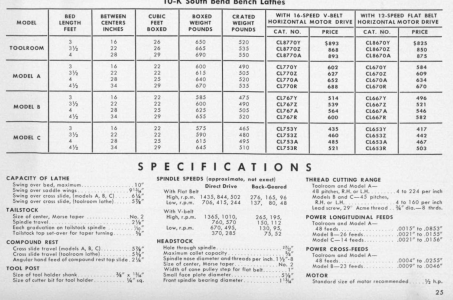

The specs on this lathe indicate a .84” bore.

Sent from my iPhone using Tapatalk

That is much larger than the specs given at lathes.uk which says 5/8" (0.625"), but would be more in line with other similar size lathes.

$900 ($675 US) doesn't seem out of line to me based on prices I see around me. If it is a dealer then rather than whittling down the price see if you can get them to throw in some tooling, you may get a better deal that way and you will need the tooling anyway.

Don't under estimate the cost of tooling, another chuck, steady rest, follow rest and drill chuck could easily add up to more than what they are asking for the lathe.

From another of your posts I gather you are disappointed in the quality of the mini-lathe which is a common complaint for those 7x lathes. While an old US made lathe is theoretically better, they are all very old with the newest dating from the late 70s / early 1980s, and most earlier. Wear could be non-existent to extreme all depending on the life they led. Smaller lathes probably had an easier life doing light commercial work or as a hobby machine, but they probably are more prone to a lack of proper maintenance so still need a good examination. When I see a machine missing parts it suggests neglect to me, not the lathe only used by an old machinist on Sundays that we all hope to find.