- Joined

- Nov 22, 2022

- Messages

- 358

Got the DRO bracket fabricated. I drilled and tapped the top cover 8-32

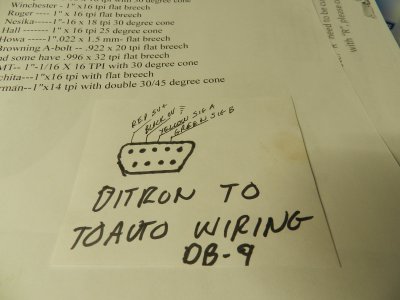

The people at "TOAUTO" have been great! They checked in several times to ask me if everything went ok with their DRO, The other company I bought the magnetic scale for the x-axis from is ignoring me, I am going to give them a couple more days, And then I am going to let people know who not to deal with.

The people at "TOAUTO" have been great! They checked in several times to ask me if everything went ok with their DRO, The other company I bought the magnetic scale for the x-axis from is ignoring me, I am going to give them a couple more days, And then I am going to let people know who not to deal with.