- Joined

- Nov 22, 2022

- Messages

- 359

Update:

Sorry it's been a while, But I came down with something that knocked me for a loop, When I already have some major health issues.

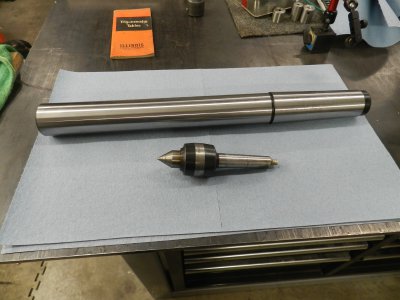

Anyway, I was able to get the lathe headstock aligned to within 2 tenths up and down over 8 or 9 inches, And 1 tenth side to side, So I feel good about that. I bought a #5 MT Test bar and I will include a pic of it next to a #2 MT live center just so you will have an idea of how HUGE it is. I also repaired the last oil leak at the top change gear shaft. I also removed the cover for the transmission and lubed the bearings and gears. Which they say you are supposed to do each time you use it, But I think most have never done it.

Next is to install a DRO.

Sorry it's been a while, But I came down with something that knocked me for a loop, When I already have some major health issues.

Anyway, I was able to get the lathe headstock aligned to within 2 tenths up and down over 8 or 9 inches, And 1 tenth side to side, So I feel good about that. I bought a #5 MT Test bar and I will include a pic of it next to a #2 MT live center just so you will have an idea of how HUGE it is. I also repaired the last oil leak at the top change gear shaft. I also removed the cover for the transmission and lubed the bearings and gears. Which they say you are supposed to do each time you use it, But I think most have never done it.

Next is to install a DRO.