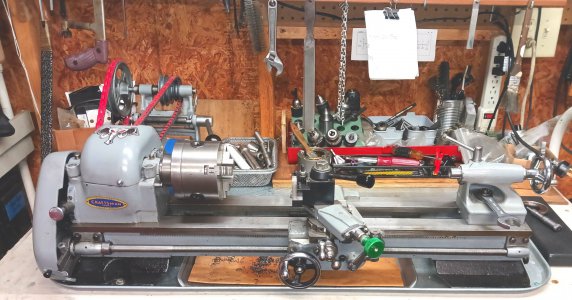

Okay so I've got some good news the guy I bought the lathe has another 4 jaw of the exact same kind but it's missing some of the Jaws but I can reuse the Jaws from my old one and refit them, and he's got a back plate that he's going to bring to me as well and I figured I can retrofit the other back plate to the three jaw if needed, plus he's probably bringing me a bunch of other stuff and I'm going to start another thread on Monday because he's bringing me a Walker Turner floor model drill press that needs to be put back together, everything's been cleaned up on it already and repainted it just needs a motor.