- Joined

- Feb 27, 2023

- Messages

- 76

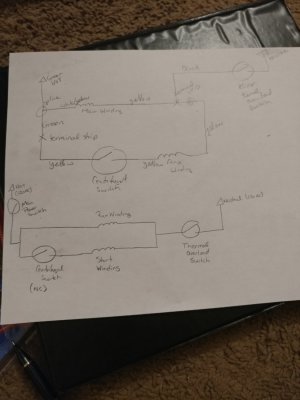

Well I can still kind of see the colors and make out what they are and luckily I just had someone send me pictures of there motor that they restored before and after so now I have pictures of the wiring so tomorrow I'm going to get on that and rewire the thing correctly.On a motor that old, all the cloth insulation would have likely turned the same color so as to not make a difference. At least, every old motor I have worked on was that way. The best way is still to use a multimeter to double check the circuits. Once you learn it, you will be able to do it every time. Eventually, if you like it enough you will find yourself with a megohmmeter checking the insulation of each winding.