- Joined

- Dec 18, 2019

- Messages

- 6,464

A while back one of the shelves in our kitchen collapsed. It is a corner cabinet in which we store various staples. This shelf had some weight on it, since there were bags of flour, sugar, olive oil and stuff on it. Since the kitchen was remodeled only 2 years ago, we contacted the kitchen guy about it. He said to us, you have a lot of weight on the shelf. I'm thinking to myself, you sold me a shelf that is only for knicknacks? I said, this is where we keep things in the kitchen, what can you do to fix it? He takes some measurements and says he will order something.

Time goes by. A lot of time goes by, then even more. In the meantime, we have kitchen stuff in other rooms, because the shelf isn't fixed. Yes, we are tired of this. We have contacted the guy, but we are getting the feeling that it will be a long time, or never, when he comes back, with the mythical part(s).

Examining the cabinet reveals the shelf is undersized for the area. This is somewhat understandable, since one needs to tilt the shelf in to get the shelf into the cabinet. But the shelf seems to be held in place by the same little clips that are used for the normal rectangular shelves. These clips basically have a pin that goes in a flat bottomed hole in the cabinet. The gap between the interior cabinet wall and the shelf is about 0.300" on both sides. This allows the shelf to pry the dowel pin right out of the hole.

There are only 5 clips that hold up the pentagon shaped shelf, 2 on each side, and one in the far rear.

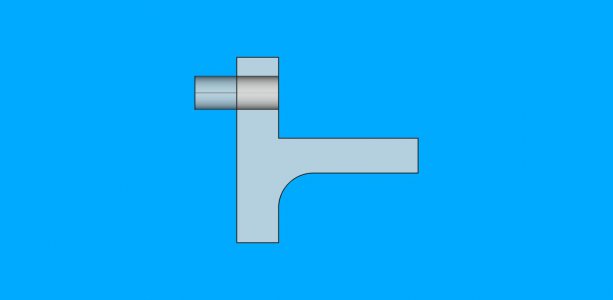

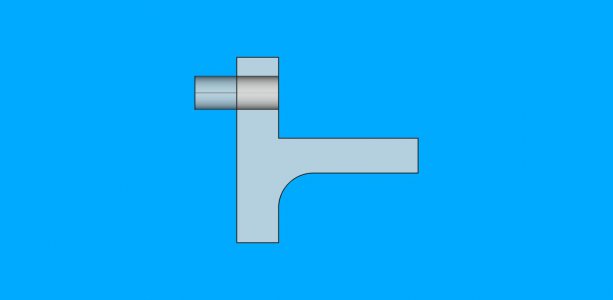

I redesigned a clip to be thicker and have a section the extends below the support. Kind of like this picture.

I had a friend print two for me, that were thinner, and it was obvious, that the printed brackets were the wrong size, and that they never could hold a load. So this design is version 3.

The thickness of the bracket should take up some of the slop of the shelf, I hope. It is 0.300" thick. The pin measure 0.245". I was thinking of making the bracket out of 6061 and pressing in a steel pin. Having never done press fits, is there anything special I need to do? For a 1/4" pin, what size should the hole be? 0.001" undersized? Then heat the aluminum and drop the pin in place?

I'll try to get a picture of the cabinet interior, but it is one of those wide angle shots that is really hard to make.

If anyone has had to do this and knows a better thing to do, please let me know. I don't want to make too many of these, especially if they don't work!

Time goes by. A lot of time goes by, then even more. In the meantime, we have kitchen stuff in other rooms, because the shelf isn't fixed. Yes, we are tired of this. We have contacted the guy, but we are getting the feeling that it will be a long time, or never, when he comes back, with the mythical part(s).

Examining the cabinet reveals the shelf is undersized for the area. This is somewhat understandable, since one needs to tilt the shelf in to get the shelf into the cabinet. But the shelf seems to be held in place by the same little clips that are used for the normal rectangular shelves. These clips basically have a pin that goes in a flat bottomed hole in the cabinet. The gap between the interior cabinet wall and the shelf is about 0.300" on both sides. This allows the shelf to pry the dowel pin right out of the hole.

There are only 5 clips that hold up the pentagon shaped shelf, 2 on each side, and one in the far rear.

I redesigned a clip to be thicker and have a section the extends below the support. Kind of like this picture.

I had a friend print two for me, that were thinner, and it was obvious, that the printed brackets were the wrong size, and that they never could hold a load. So this design is version 3.

The thickness of the bracket should take up some of the slop of the shelf, I hope. It is 0.300" thick. The pin measure 0.245". I was thinking of making the bracket out of 6061 and pressing in a steel pin. Having never done press fits, is there anything special I need to do? For a 1/4" pin, what size should the hole be? 0.001" undersized? Then heat the aluminum and drop the pin in place?

I'll try to get a picture of the cabinet interior, but it is one of those wide angle shots that is really hard to make.

If anyone has had to do this and knows a better thing to do, please let me know. I don't want to make too many of these, especially if they don't work!