- Joined

- Dec 18, 2019

- Messages

- 6,464

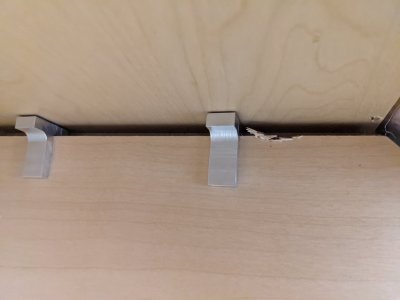

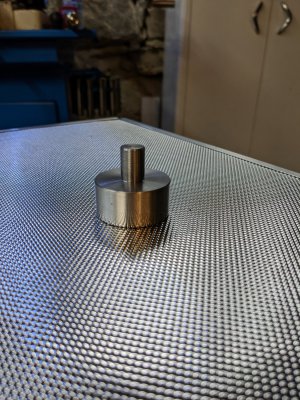

A little more shop time. Made up some more brackets, or rather the basic shape, yesterday. Was able to fit two pieces in the vise, so machined them both at once. That sure helped, along with kind of knowing what to do this time! Hogged out material and then did a few passes with the ball mill. This afternoon cut them into brackets using the slitting saw. Was able to cut two at once which helped speed up the slow slitting saw cutting. So now I have 9 brackets. Really only need 8, but each block gave me three at a time, so 9 it is. Was good to knock this off today. Have a bit of de-burring to do, but overall happy with them so far.

Waiting for the reamer set I ordered to show up, then I will drill them and ream them in the same setup. Will fixture it so it will just be step and repeat.

Waiting for the reamer set I ordered to show up, then I will drill them and ream them in the same setup. Will fixture it so it will just be step and repeat.