- Joined

- Nov 27, 2012

- Messages

- 7,855

That's very interesting Mike, I've never heard that before. All the formulas & calculators I use & have seen are to prevent double tracking like how I mentioned earlier. They've always worked for me & that's how I was taught. 2 general formulas that I'm aware of, one for diametral pitch wheels & another for circular pitch wheels.

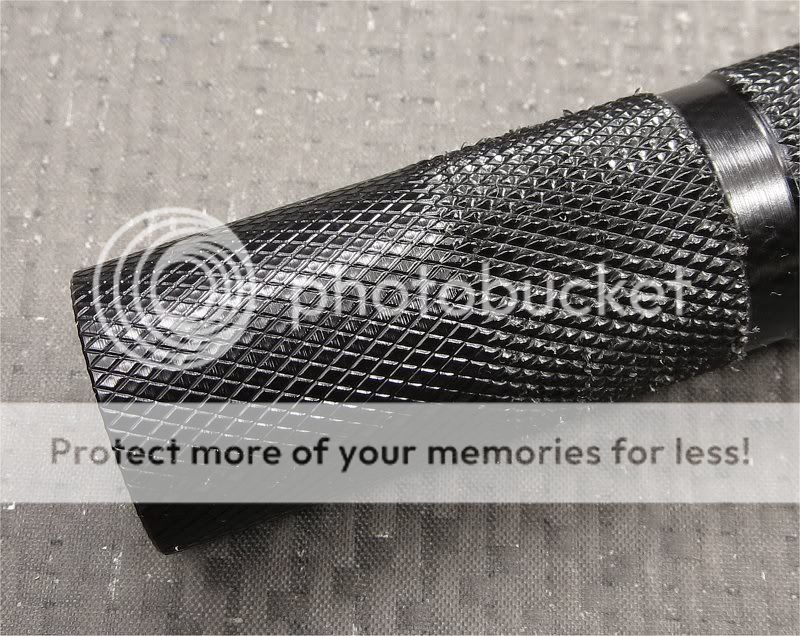

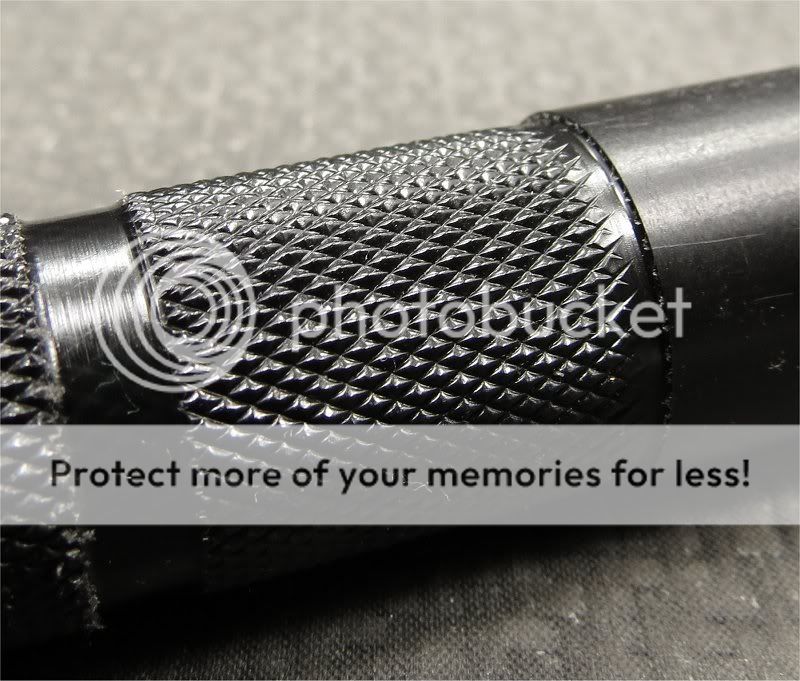

I don't even know how to make a knurl for a spec'd size, I have an idea but it's just an idea & have no idea how it's actually done. I don't make production parts nor have I ever needed to make a knurl to a specific OD for a press fit so I really don't care. The main purpose for knurling is for grip but for me, cosmetic comes first, then functionality cause I'm anal like that, lol. Like Brino I don't care about the finished size.

When I knurl hard materials like SS & Ti that work harden easy, there's no way I can just continue feeding to make the knurl form & track properly. I don't even like to make a second pass on hard materials, I do it in one shot. I've tried & tried when I was learning, not once did it work for me. The materials are too hard to displace that much & will work harden before coming out right. I always calculate for diameters & I have a pretty high success rate even though I dread knurling every single time on those materials.

Lots of good info in this thread though, whatever works for someone is all that matters.

Accu-Trak has very good info on knurling. https://www.accu-trak.com/technicalinfo.html

I don't even know how to make a knurl for a spec'd size, I have an idea but it's just an idea & have no idea how it's actually done. I don't make production parts nor have I ever needed to make a knurl to a specific OD for a press fit so I really don't care. The main purpose for knurling is for grip but for me, cosmetic comes first, then functionality cause I'm anal like that, lol. Like Brino I don't care about the finished size.

When I knurl hard materials like SS & Ti that work harden easy, there's no way I can just continue feeding to make the knurl form & track properly. I don't even like to make a second pass on hard materials, I do it in one shot. I've tried & tried when I was learning, not once did it work for me. The materials are too hard to displace that much & will work harden before coming out right. I always calculate for diameters & I have a pretty high success rate even though I dread knurling every single time on those materials.

Lots of good info in this thread though, whatever works for someone is all that matters.

Accu-Trak has very good info on knurling. https://www.accu-trak.com/technicalinfo.html