- Joined

- Oct 4, 2020

- Messages

- 484

Looking for a new high quality 16ER type laydown toolholder.

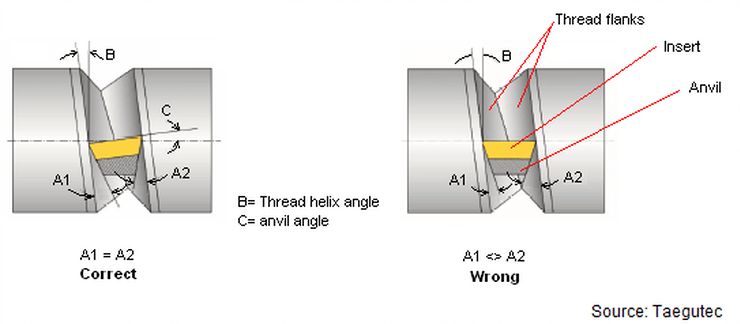

What role does the insert/bushing/shim play? (The part that would be under the insert) - They have 3 different pointy bits that all look a little different but I don't know why.

Also, what is the screw in the side of the holder, under the shim for?

Example:

What role does the insert/bushing/shim play? (The part that would be under the insert) - They have 3 different pointy bits that all look a little different but I don't know why.

Also, what is the screw in the side of the holder, under the shim for?

Example: