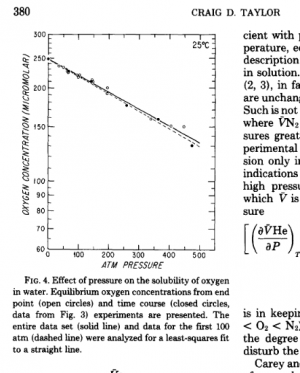

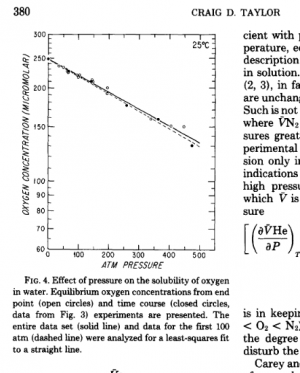

Just a couple more thoughts. Since the observable rust always forms at the splash line/zone does this mean that the steel is not rusting (much, or as rapidly) under the water or above it? When the pressure is increased, as proposed in the above arguments it is being assumed that there is more Oxygen to accelerate the rusting process. But the amount of oxygen dissolved into water with pressure actually goes down not up. For this discussion it does not change a lot, but still it does not go up. (see plot below)

So maybe all of this is a bit more complex than is being discussed here. My guess is that impurities in the water, especially ionic, play a big role in the rates. In the marine environment is it the salts (chlorine) that determines the rates? When they salt the roads cars rust. Likewise, when you live near an ocean.

Yes, the oxygen does become depleted as rusting occurs, but when the tank is refilled it gets new oxygen. If you look at hot water heating systems the water is not changed unless there is a leak or someone drains it. The insides of steel or cast iron pipes probably rust a bit and then the rusting process shuts down. These pipes, pumps, etc lasts for decades. On the other hand hot water heaters rust out every few years as the water supply is bringing in new water with its dissolved oxygen.

Anyway, this all seems too complex to decide if the air should be drained out of the compressor tank or not and how this depends upon the use cycles. Do we need to run to the compressor at the end of each day's use and drain the air and the water or should we spend our time making more money so that we can buy a new compressor/tank?? Also, maybe we should not drain the water at all, for if the water level steadily increases and the rusting mostly occurs at the splash zone then the tank life might be greater if the splash zone was slowing rising in the tank!???

So maybe all of this is a bit more complex than is being discussed here. My guess is that impurities in the water, especially ionic, play a big role in the rates. In the marine environment is it the salts (chlorine) that determines the rates? When they salt the roads cars rust. Likewise, when you live near an ocean.

Yes, the oxygen does become depleted as rusting occurs, but when the tank is refilled it gets new oxygen. If you look at hot water heating systems the water is not changed unless there is a leak or someone drains it. The insides of steel or cast iron pipes probably rust a bit and then the rusting process shuts down. These pipes, pumps, etc lasts for decades. On the other hand hot water heaters rust out every few years as the water supply is bringing in new water with its dissolved oxygen.

Anyway, this all seems too complex to decide if the air should be drained out of the compressor tank or not and how this depends upon the use cycles. Do we need to run to the compressor at the end of each day's use and drain the air and the water or should we spend our time making more money so that we can buy a new compressor/tank?? Also, maybe we should not drain the water at all, for if the water level steadily increases and the rusting mostly occurs at the splash zone then the tank life might be greater if the splash zone was slowing rising in the tank!???