-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Little john

- Thread starter COLIN

- Start date

- Joined

- Feb 22, 2012

- Messages

- 924

those are nice lathes.

I was tempted to get a Five a while ago, but because I couldn't find parts supplies etc I ended up passing. My best bet would be to look at 3rd party companies like Boston Gears that can get you the gears you need, but you would have to know the size and tooth count of the gears in question - do you have documentation and/or existing (broken/worn off?) gears to get those numbers from?

I was tempted to get a Five a while ago, but because I couldn't find parts supplies etc I ended up passing. My best bet would be to look at 3rd party companies like Boston Gears that can get you the gears you need, but you would have to know the size and tooth count of the gears in question - do you have documentation and/or existing (broken/worn off?) gears to get those numbers from?

those are nice lathes.

I was tempted to get a Five a while ago, but because I couldn't find parts supplies etc I ended up passing. My best bet would be to look at 3rd party companies like Boston Gears that can get you the gears you need, but you would have to know the size and tooth count of the gears in question - do you have documentation and/or existing (broken/worn off?) gears to get those numbers from?

Hi thanks for the interest, I was looking for a simple fix! (cost). Luckily there is a small company in England who can make all the gears and some other parts that may be needed.

E-Mail:Tony@lathes.co.uk Tony Grffiths, Wardlow, Tideswell, Buxton, Derbyshire, SK17 8RP. UK. email:sales@lathes.co.uk www.lathes.co.uk

- Joined

- Sep 24, 2010

- Messages

- 3,096

Colin,

Welcome to the group!!!! You might also want to consider starting a thread in the wanted to buy or for sale areas and tell the folks what you are looking ofr. A lot of the old timers dont read the intro so they miss your need. This is a very ;aid back group that prides itself on being a calm and freindly place to go and discuss machining in a non threatening environement. I would suggest that you get acquanted with a few of your fellow country men who are members and arrainge a coffee or pub meeting to put a face on the crowd. There are a good many member here from the UK so ask around and see who might be close by and is interested in visiting and sharing there info one on one. I am not familiar with that brand of machine, but I would think that you could find some documentation and get the gears you need either from a set or made to fit by someone locally. Once you get a bit of practise you may just be able to make them yourself. Fellows will be glad to help you do that if that is what you decide to do. Otherwise welcome to the gang, and remember your opinion counts here, sp dont be afraid to speak up wherever your interests take you.

Bob

Welcome to the group!!!! You might also want to consider starting a thread in the wanted to buy or for sale areas and tell the folks what you are looking ofr. A lot of the old timers dont read the intro so they miss your need. This is a very ;aid back group that prides itself on being a calm and freindly place to go and discuss machining in a non threatening environement. I would suggest that you get acquanted with a few of your fellow country men who are members and arrainge a coffee or pub meeting to put a face on the crowd. There are a good many member here from the UK so ask around and see who might be close by and is interested in visiting and sharing there info one on one. I am not familiar with that brand of machine, but I would think that you could find some documentation and get the gears you need either from a set or made to fit by someone locally. Once you get a bit of practise you may just be able to make them yourself. Fellows will be glad to help you do that if that is what you decide to do. Otherwise welcome to the gang, and remember your opinion counts here, sp dont be afraid to speak up wherever your interests take you.

Bob

- Joined

- Feb 15, 2013

- Messages

- 45

Colin, how many and which wheels do you need? I recently cut five for my LittleJohn. And made a new rack pinion. And took the cross slide intermediate wheel to the dentist to replace three missing teeth. And made a cross slide pinion

I'm getting good at LittleJohn wheel cutting

Richard

I'm getting good at LittleJohn wheel cutting

Richard

Colin, how many and which wheels do you need? I recently cut five for my LittleJohn. And made a new rack pinion. And took the cross slide intermediate wheel to the dentist to replace three missing teeth. And made a cross slide pinion

I'm getting good at LittleJohn wheel cutting

Richard

Hi Richard,

I'm looking firstly for a 44 tooth gear for the metric conversion, I already have the 52 tooth gear, afterwards it may be time to invest in other gears. the lathe only came with what was in the basic end gearbox. Your help and interest is much appreciated. I do not like Dentists.

Thanks Colin.

- Joined

- Feb 15, 2013

- Messages

- 45

Hi Richard,

I'm looking firstly for a 44 tooth gear for the metric conversion, I already have the 52 tooth gear, afterwards it may be time to invest in other gears. the lathe only came with what was in the basic end gearbox. Your help and interest is much appreciated. I do not like Dentists.

Thanks Colin.

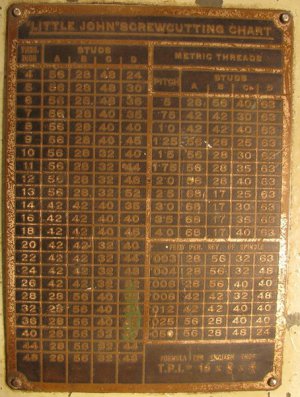

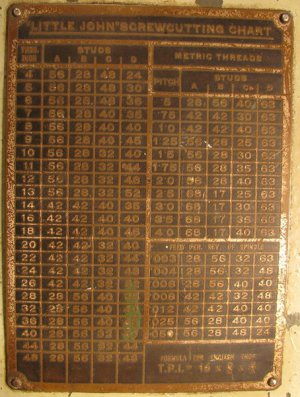

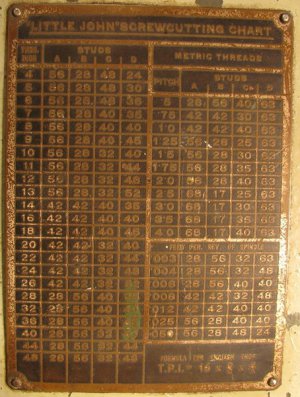

Is yours a later Little John? I'm asking because I have a paper copy of the thread cutting table, so I made up the missing wheels and found they wouldn't fit. I had to drop spindle B down and cut away the casing to make it work. I have recently bought a second Little John (I'm planning to breed them) which has a different chart.

This lathe uses a 63 and a 68 tooth wheel to cut metric, neither of which I have. I suspect that they were an option

If the distance between shafts A and B is around 2 5/8" this is the correct chart. If it is around 2 13/16" the chart you have is correct

Richard

is yours a later little john? I'm asking because i have a paper copy of the thread cutting table, so i made up the missing wheels and found they wouldn't fit. I had to drop spindle b down and cut away the casing to make it work. I have recently bought a second little john (i'm planning to breed them) which has a different chart.

this lathe uses a 63 and a 68 tooth wheel to cut metric, neither of which i have. I suspect that they were an option

if the distance between shafts a and b is around 2 5/8" this is the correct chart. If it is around 2 13/16" the chart you have is correct

richard

i have just checked the distance between a to b and it appears to be 2 5/8"

is yours a later little john? I'm asking because i have a paper copy of the thread cutting table, so i made up the missing wheels and found they wouldn't fit. I had to drop spindle b down and cut away the casing to make it work. I have recently bought a second little john (i'm planning to breed them) which has a different chart.

this lathe uses a 63 and a 68 tooth wheel to cut metric, neither of which i have. I suspect that they were an option

if the distance between shafts a and b is around 2 5/8" this is the correct chart. If it is around 2 13/16" the chart you have is correct

richard

hi richard

i think that my lj is an early mk1.

I have just checked the distance between a to b centres and it appears to be 2 5/8" i have tried to upload a picture of my gearbox cover at 'manage attachments' good luck, but i seem to be doing something wrong, it would seem that mine does not use 63/68 tooth gears at all, my cover tells me to remove the gears at the rear of b/c and replace with 52 on b and 44 on c.

Colin.

- Joined

- Feb 15, 2013

- Messages

- 45

Excellent. So you have two 30 tooth wheels, two 60 tooth wheels and a pair of 45 wheels for the A and B shafts? I had to make most of those

Have you checked that you can remove the wheels on the back of the B and C shafts? I guess that you will be able to. I couldn't on mine so I remachined the shafts

It does sound like you only need a 44 tooth wheel

Richard

Have you checked that you can remove the wheels on the back of the B and C shafts? I guess that you will be able to. I couldn't on mine so I remachined the shafts

It does sound like you only need a 44 tooth wheel

Richard